When there is a global shortage of a particular manufactured good, people look to science and technology to develop new solutions to the problem. Styrene-butadiene rubber is used to create everything from seat belts to tyres, seals, and gaskets. It is a rubber that can be used for many different things and has many multiple approaches. It contributes significantly to modern technology because of its long-range elasticity and diverse applications.

Visit this Page for More Information: Start a Business in Rubber Manufacturing Industry

During the 1930s natural rubber supply was cut off, leading German scientists to develop this. It is a fundamental component of both the industrial and automotive industries. Owing to its unique collaborative properties with additives and fillers, styrene-butadiene rubber (SBR) is a synthetic polymer that is primarily used in the tire industry.

Vehicle tires are made with the vast majority (75%) of common rubber. 60% of the world’s rubber market is made up of natural rubber and styrene-butadiene rubber (SBR), whose large-scale manufacturing is done in an environmentally friendly manner and which is why it is preferred as a matrix material in the tire industry.

Families of synthetic rubbers made from styrene and butadiene are referred to as styrene-butadiene (SBR) rubber. In the presence of additive protection, these materials exhibit good abrasion resistance and aging stability. Car tires are made from various types of SBR to a degree of about 50%. The styrene/butadiene ratio affects the polymer’s characteristics; for example, rubbers with a high styrene content are harder and less rubbery.

SBR consists primarily of butadiene (CH2=CH-CH=CH2) and styrene (CH2=CHC6H5), about 75% and 25%, respectively.

Styrene-butadiene rubber’s main characteristics are as follows:

- Since it is readily available and reasonably priced, it is widely used.

- High tensile strength, abrasion resistance, and resilience are all features of SBR.

- It is flexible in low temperatures and has a respectable resistance.

- In addition, it is resistant to water, chemicals, alcohol, ketone, and aldehydes.

- Its ability to accommodate substantial amounts of fillers, which improves its properties, makes it crack-resistant.

| Fillers | |

| Carbon black | Increases SBR’s resistance to UV, abrasion, and strength. |

| China clay | Is utilized to strengthen and reinforce rubber products that aren’t black. |

| Calcium carbonate | Reduces the product’s final quantity. |

| Silica | Brings about an improvement in electrical insulation, dimensional stability, and thermal conductivity. |

| Filaments | Reduce the finished product’s stretchability. |

Read Similar Articles: Rubber Projects

Processing and compounding Synthetic rubber:

SBR is a thermoplastic or thermoset that is available to rubber processors in the form of large bales, with exception of a few other thermoplastics or thermosets (which are supplied as granules or liquid resins). Elastomers and additives are combined to create rubbers in the first step of processing. Rubbers are then shaped using a variety of processing techniques.

SBR is frequently blended with additives like

- For vulcanization, sulfur.

- Rubber can be extended with reinforcing or non-reinforcing fillers to improve its mechanical properties and cut costs.

Compounding improves the properties, cost, and processability of styrene-butadiene rubber to meet the needs of a specific application.

Click here to send your queries/Contact Us

Production Key Elements

When manufacturing SBR, there are a few important variables to take into account, including the process type, the styrene-to-butadiene ratio, and the kind of solvent.

Market Analysis:

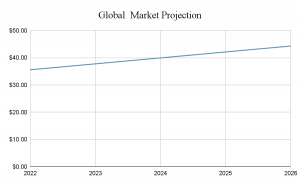

According to a report by ResearchAndMarkets, the global market for styrene butadiene rubber (SBR) is projected to grow at a compound annual growth rate (CAGR) of 6.2% from $33.52 billion in 2021 to $35.59 billion in 2022. At a CAGR of 5.6%, the market is poised $44.31 billion in 2026.

Asahi Kasei, Lanxess, Bridgestone, Michelin, China Petroleum & Chemical, JSR, The Goodyear Tire & Rubber, Sinopec, Eastman, and SIBUR are significant market participants for styrene-butadiene rubber.

Analysis In terms of region, Asia Pacific dominated the styrene-butadiene rubber market in 2021. The second-largest market for styrene-butadiene rubber was in Western Europe.

Related Feasibility Study Reports: Rubber and Rubber Products, Rubber based Industries, Natural Rubber, Synthetic Rubber, Tyre, Tire, Rubber Chemicals, Industrial Rubber Products, Rubber for Automobile, Extruded Rubber, Medical, Adhesives & Sealants, Belt, Footwear, Gloves, Injection Parts

Analysis In terms of region, Asia Pacific dominated the styrene-butadiene rubber market in 2021. The second-largest market for styrene-butadiene rubber was in Western Europe.

Evaluation by Type, The solution styrene butadiene rubber (SBR) industry is set to hold the largest share during the forecast period. The widespread use of solution SBR in the tire and footwear industries is a factor in the increase. SBR is frequently used in the production of footwear due to its flexibility, potent anti-slip properties, durability, potent abrasion properties, and density. With an 8.9% annual growth rate, more than 22 billion pairs of shoes were produced worldwide in 2021, and 13.5 billion pairs were exported during the same period.

Application-specific analysis: During the forecast period, it is expected that the tire segment will hold the majority of the market share. The market for styrene butadiene rubber (SBR) is anticipated to grow due to the widespread use of SBR in the production of high-performance tires and improved vehicle performance and fuel economy. This is especially advantageous for motorcycles and high-performance radial tires.

Taking everything into account, the Asia Pacific region receives the most finances. Secondly, the revenue graph is influenced by the solution SBR segment. Thirdly, the tire market continues to have a sizable presence in the application market.

Read our Books Here: Rubber Processing And Compounding Technology Books, Rubber Processing Chemicals and Leather Processing Technology Books

India’s Market Analysis:

India’s automotive industry, which can be divided into two categories: the tire sector and the non-tire sector, is the country’s biggest consumer of SBR. The tire industry includes all different kinds of car tires, including radial and conventional tires, as well as tire exports. The non-tire sector is made up of medium-sized, small-scale, and tiny businesses that manufacture sophisticated industrial products with cutting-edge technology.

Simply put, the various applications include footwear, adhesives, polymer modification, automotive tires, and other uses. Retail sales, other channel sales, and direct/institutional sales make up the distribution channels.

Visit the page Select and Choose the Right Business Startup for You for sorting out the questions arising in your mind before starting any business and know which start-up you can plan.

We, at NPCS, endeavor to make business selection a simple and convenient step for any entrepreneur/startup. Our expert team, by capitalizing on its dexterity and decade’s long experience in the field, has created a list of profitable ventures for entrepreneurs who wish to diversify or venture. The list so mentioned is updated regularly to give you a regular dose of new emerging opportunities.

Heads Up:

- The styrene-butadiene rubber industry has always faced significant challenges related to safety hazards. Butadiene is used in the production of polymers and elastomers but is not sold to consumers directly due to its potential risks. Butadiene has a low water solubility and is very volatile. Butadiene exposure over an extended period is harmful to human health.

- High concentrations can harm the central nervous system and cause comas, headaches, nausea, fatigue, and decreased blood pressure. 3-Butadiene has been identified as a potential carcinogen by the International Agency for Research on Cancer.

- The production of a lot of heat and smoke from the consumption of rubber tire waste is one of the primary factors influencing the change in global temperature.

Niir Project Consultancy Services (NPCS) has produced one of the reports on the subject ‘Start Manufacturing of SBR (Styrene Butadiene Rubber)’. The sector report covers all the aspects of business, from accessing the market, confirming the availability of various necessities such as raw materials, key elements, and processing to projecting financial demands. The report by NPCS has assisted engineers, project collaborators, and industrial consultancy firms in India and worldwide. With the report on various business ideas, NPCS publishes technology, technical, reference, self-employment, and startup books, directories, business and industry databases, and other information you can peruse on the web.

Click here to send your queries/Contact Us

Reasons for Buying NIIR Report:

● Our research report helps you get a detailed picture of the industry by providing an overview of the industry along with the market structure and classification.

● Our report provides market analysis covering major growth driving factors for the industry, the latest market trends and the regulatory framework of the industry.

● Our Report provides an analysis and in-depth financial comparison of major Players / Competitors.

● Our Report provides indispensable buyers data with their company financials as well as the contact details, which can be an important tool in identifying the target customers.

● Our report provides forecasts of key parameters which help to anticipate the industry performance.

● We use reliable sources of information and databases. And information from such sources is processed by us and included in the report.

See More Links:

- Start a Business in Asia

- Start a Business in Potential Countries for Doing Business

- Best Industry for Doing Business

- Business Ideas with Low, Medium & High Investment

- Looking for Most Demandable Business Ideas for Startups

- Startup Consulting Services

- Start a Business in Africa

- Start a Business in India

- Start a Business in Middle East

- Related Videos

- Related Books

- Related Projects

- Related Market Research Reports

SS_20Art22