Profitable Manufacturing Opportunities in 2026

The global shift toward sustainable materials, renewable energy, and eco-conscious manufacturing is unlocking new business opportunities for entrepreneurs. With industries worldwide focusing on reducing carbon footprints and enhancing material efficiency, the demand for innovative manufacturing ventures is stronger than ever.

Among the numerous possibilities, three product categories stand out in 2025:

- Ferrosilicon – a vital alloy in steelmaking and clean energy applications.

- Vedic Paint from Cow Dung – a natural, eco-friendly coating revolutionizing the paint industry.

- Bamboo Wood Pellets – a renewable biomass fuel offering sustainable energy alternatives.

This long-form guide explores these industries from a startup and business perspective, highlighting their composition, production processes, market outlook, and key considerations for setting up a manufacturing unit.

1. Ferrosilicon: Alloying the Future of Steel

What Is Ferrosilicon?

Ferrosilicon is an iron–silicon alloy containing 45–90% silicon, along with trace elements such as aluminum and carbon. It serves as both a deoxidizer and alloying agent in steelmaking, removing oxygen from molten steel and enhancing its strength, toughness, and corrosion resistance.

High-purity grades of ferrosilicon (>90% Si) are used in semiconductor and solar applications, particularly for producing solar-grade silicon. Common grades include FeSi 75, FeSi 72, and FeSi 65, which vary in silicon content.

Ferrosilicon Manufacturing Process

Ferrosilicon manufacturing primarily involves smelting quartzite (SiO?), coke, and iron scrap in an electric arc furnace.

Main steps include:

- Smelting in an Electric Arc Furnace

Silica reacts with carbon to form silicon through the reaction:

SiO? + 2C ? Si + 2CO

Electric arc furnaces (EAFs) ensure precise control of temperature and current. - Refining and Impurity Removal

Refining eliminates unwanted elements such as aluminum, calcium, and carbon to produce high-purity alloys. - Sizing and Packaging

- Lumps (10–50 mm) – used in deoxidizing steel.

- Grains or powders (1–8 mm) – used in cast iron and mineral processing.

Key resources required: high-purity quartz (>97.5% SiO?), coke (fixed carbon >82%), and reliable electric power, which is a major cost component.

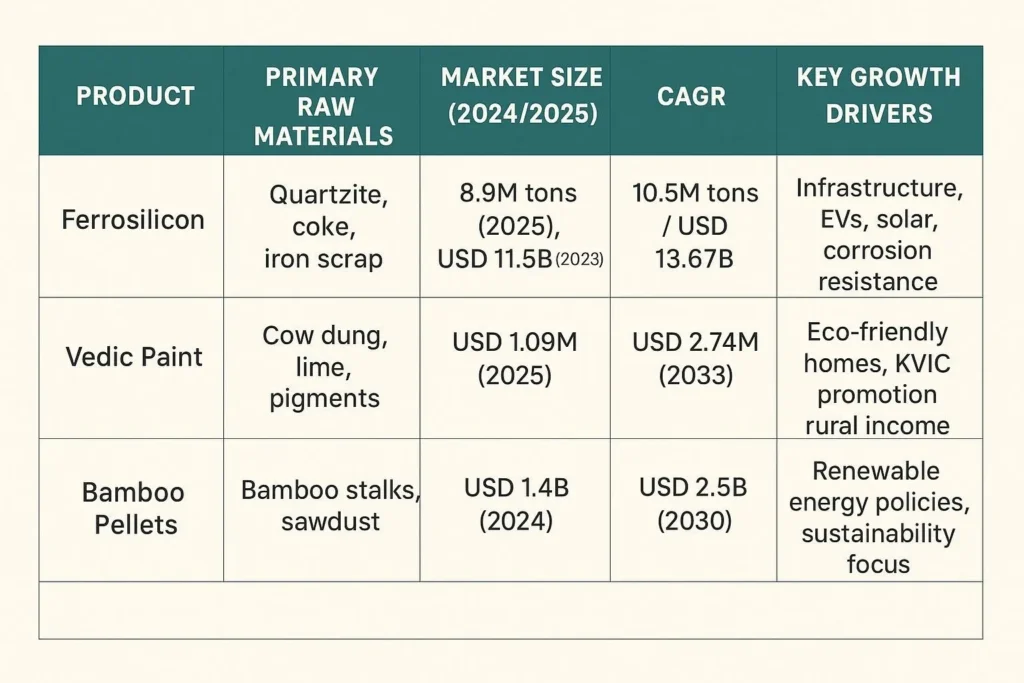

Market Outlook and Growth Trends

The ferrosilicon market is largely driven by steel production, which consumes about 82% of global output.

According to Mordor Intelligence:

- Global demand: from 8.87 million tons (2025) to 10.48 million tons (2030) (CAGR 3.39%).

- Market value: expected to reach USD 13.67 billion by 2030 from USD 11.50 billion in 2023.

- Asia-Pacific dominates with 58–66% market share.

- Photovoltaic applications are growing fastest at a 4.96% CAGR.

Demand Drivers

- Infrastructure & Construction Boom – High-strength steels boost consumption.

- Electric Vehicles (EVs) – Use of silicon steel in traction motors.

- Corrosion-Resistant Materials – Growing preference for silicon-enhanced coatings.

- Solar Energy – High-purity ferrosilicon serves as a base for solar silicon.

Project Report on:- Ferro Alloys

Challenges and Risks

- Volatile raw material and power costs

- Environmental regulations – up to 5 tons of CO? emitted per ton of alloy

- Substitutes and new materials – aluminum or manganese-based deoxidizers

- Technology barriers – high CAPEX for efficient furnaces

How to Start a Ferrosilicon Manufacturing Unit

- Conduct Market & Feasibility Research

Assess demand, supply, pricing, and ROI. - Secure Raw Materials

Quartzite, coke, and iron scrap through long-term contracts. - Select Equipment & Technology

Install EAFs (12–30 MW), crushers, screens, and pollution control units. - Choose Location

Prioritize access to raw materials, power, and logistics. - Ensure Compliance

Obtain environmental and safety permits, ISO 9001/14001 certification.

Read Article on:- Ferro Alloys

2. Vedic Paint from Cow Dung: Blending Tradition and Sustainability

Concept and Composition

Vedic Paint (also called Prakritik Paint or Cow Dung Paint) is a natural, eco-friendly coating made from cow dung, lime, clay, and plant-based binders. It offers antibacterial, antifungal, and odor-free protection for walls.

This concept, rooted in Indian tradition, has been modernized into a low-VOC, breathable paint with growing market potential.

Manufacturing Process

- Raw Material Collection – Cow dung from farms or gaushalas is collected.

- Cleaning & Processing – Dung is cleaned and mixed with lime/clay.

- Mixing & Grinding – Pigments and binders (casein, natural gums) are added.

- Filtration & Packaging – The paint is filtered and packaged as distemper or emulsion.

Essential equipment: grinders, mixers, dispersion units, and filtration systems.

Advantages and Unique Selling Points

- 100% eco-friendly and non-toxic

- Antibacterial and antifungal

- Breathable & odor-free

- Thermal insulation properties

- Low-cost, locally sourced raw materials

Related Article:- Paint and Coatings Manufacturing Industry.

Market Outlook

According to industry estimates:

- Indian cow dung paint market: USD 1.09 million (FY2025) ? USD 2.74 million (FY2033) (CAGR 12.24%).

- Supported by KVIC’s “Khadi Prakritik Paint” initiative under government programs like Godhan Nyay Yojana.

- The global eco-friendly paint market: USD 11.54 billion (2024) ? USD 19.25 billion (2033) (CAGR 6.7%).

Major drivers: environmental awareness, green building norms, and preference for low-VOC paints.

Business Setup Guide

- Market Analysis – Target eco-conscious customers and institutional buyers.

- Technology & Raw Material Sourcing – Secure cow dung supply, lime, and natural pigments.

- Quality Control – Follow BIS standards for paint quality and finish.

- Branding & Marketing – Emphasize cultural heritage and sustainability.

- Government Incentives – Access training, grants, and marketing support via KVIC schemes.

Challenges

- Low consumer awareness about natural paints.

- Quality perception vs synthetic paints.

- Consistent dung supply and hygienic processing.

Project Report on:- Paint Industry

3. Bamboo Wood Pellets: A Renewable Fuel Revolution

Overview

Bamboo wood pellets are compact biomass fuels made from bamboo stalks and sawdust. With high calorific value (~4800 kcal/kg) and low ash content (~1.1%), they are ideal for heating, power generation, and agricultural uses.

Bamboo’s rapid growth (up to 1 meter/day) makes it one of the most sustainable biomass feedstocks available.

Manufacturing Process

- Raw Material Preparation – Grinding bamboo into powder (3–4 mm).

- Drying – Reducing moisture to 15–20%.

- Pelletizing – Using flat die (small scale) or ring die (industrial) mills.

- Cooling & Packaging – Pellets are cooled, hardened, and packed.

Required equipment: drum chippers, hammer mills, dryers, pellet mills, coolers, and packing machines.

Applications and Benefits

- Heating & Cooking – Efficient alternative to LPG and natural gas.

- Industrial Boilers & Power Plants – Used for steam and energy generation.

- Agriculture – Used as mulch, organic fertilizer, and animal bedding.

- Sustainability – Utilizes bamboo waste, supporting a circular economy.

Market Size and Growth

As per TechSci Research:

- Market value: USD 1.4 billion (2024) ? USD 2.5 billion (2030)

- CAGR: 9.6%

- Asia-Pacific and North America dominate consumption.

Key drivers include renewable energy mandates, the availability of bamboo, and cost-effective biomass energy production.

Business Setup Guide

- Raw Material Access – Source bamboo from plantations or furniture units.

- Machinery Selection – Use modern ring die pellet machines for efficiency.

- Plant Layout – Ensure storage for raw and finished products.

- Quality Assurance – Maintain consistent moisture and size.

- Government Incentives – Explore renewable energy subsidies.

- Marketing – Partner with stove dealers, boiler operators, and agro companies.

Key Challenges

- High initial capital investment

- Limited infrastructure in bamboo-rich regions

- Market fluctuations in biomass fuel prices

Read Article on:- Opportunities in Bamboo Industry

Comparative Industry Snapshot

Why These Opportunities Matter for Entrepreneurs

Each of these manufacturing ventures addresses core global challenges — sustainability, energy transition, and eco-conscious production.

- Ferrosilicon supports clean energy and advanced materials.

- Vedic Paint transforms agricultural waste into a green product.

- Bamboo Pellets enable circular energy solutions.

For startups and consultants, these sectors offer a balance of profitability, scalability, and environmental relevance.

Conclusion

The next industrial decade will reward entrepreneurs who combine innovation with sustainability.

- Ferrosilicon continues to drive steelmaking and renewable energy applications.

- Vedic Paint offers eco-conscious consumers a healthy, green alternative.

- Bamboo Pellets provide renewable fuel options with growing global demand.

By conducting feasibility studies, securing raw materials, and leveraging incentives, entrepreneurs can capitalize on these high-potential manufacturing ventures and contribute to a greener industrial future.

Project Report:- Bamboo and Bamboo Products

How NPCS Can Help You

NPCS (Niir Project Consultancy Services) provides end-to-end support for entrepreneurs, including:

- Detailed Project Reports (DPR).

- Financial modeling & ROI analysis.

- Plant layout & machinery selection.

- Vendor & buyer connect.

- Licensing & compliance guidance.

With expert support, your chances of success in this high-growth sector increase significantly.

Niir Project Consultancy Services

106-E, Kamla Nagar, Opp. Mall ST,

New Delhi-110007, India.

Email: info@entrepreneurindia.co

Mobile: +91-9097075054

Website:https://www.entrepreneurindia.co