As the world shifts toward sustainability, entrepreneurs have an incredible opportunity to turn environmental challenges into profitable ventures. Stricter waste regulations, the demand for eco-friendly materials, and the rise of circular economy principles are driving a new wave of industrial innovation. here are the guide to Best Manufacturing Business Ideas in 2026

Instead of viewing waste as a problem, modern businesses are learning to treat it as a valuable resource. By converting industrial byproducts into useful materials, these ventures create both environmental and financial value.

In this article, we explore three high-potential green manufacturing sectors that blend profitability with sustainability:

- Liquid Carbon Dioxide (LCO?) Production

- Tire Recycling Units

- Bagasse-Based Biodegradable Tableware

Each of these represents a practical, scalable, and future-ready business for startups and investors.

Contents

List of Best Manufacturing Business Ideas in 2026

1. Liquid Carbon Dioxide (LCO?) Production

Overview

Liquid carbon dioxide (LCO?) is CO? gas that has been compressed and cooled into liquid form. It plays a vital role in several industries—most notably in beverages, food freezing, packaging, and pharmaceuticals.

In breweries, LCO? is used for carbonation. Food processors rely on it for quick-freezing and cold storage. Packaging companies use it in modified-atmosphere systems to extend shelf life. LCO? is also a key ingredient for producing dry ice, essential for cold-chain logistics in pharmaceuticals and perishable food transport.

LCO? is colorless, odorless, and non-toxic, making it safe for food and medical use. Industrial applications also include welding shields, sterilization, and greenhouse CO? enrichment.

Manufacturing Process

- CO? Capture: The gas is captured from industrial sources such as breweries, ethanol plants, or ammonia factories.

- Purification: Impurities and moisture are removed.

- Compression & Cooling: The clean CO? is compressed and cooled in a cryogenic system, converting it to liquid form.

- Storage: Liquid CO? is stored in insulated cryogenic tanks and distributed in cylinders or bulk tankers.

Read Related:- Books

Key Equipment:

- CO? capture and purification system

- Compressors and cryogenic refrigeration units

- Insulated storage tanks, pipelines, and pumps

Market Overview

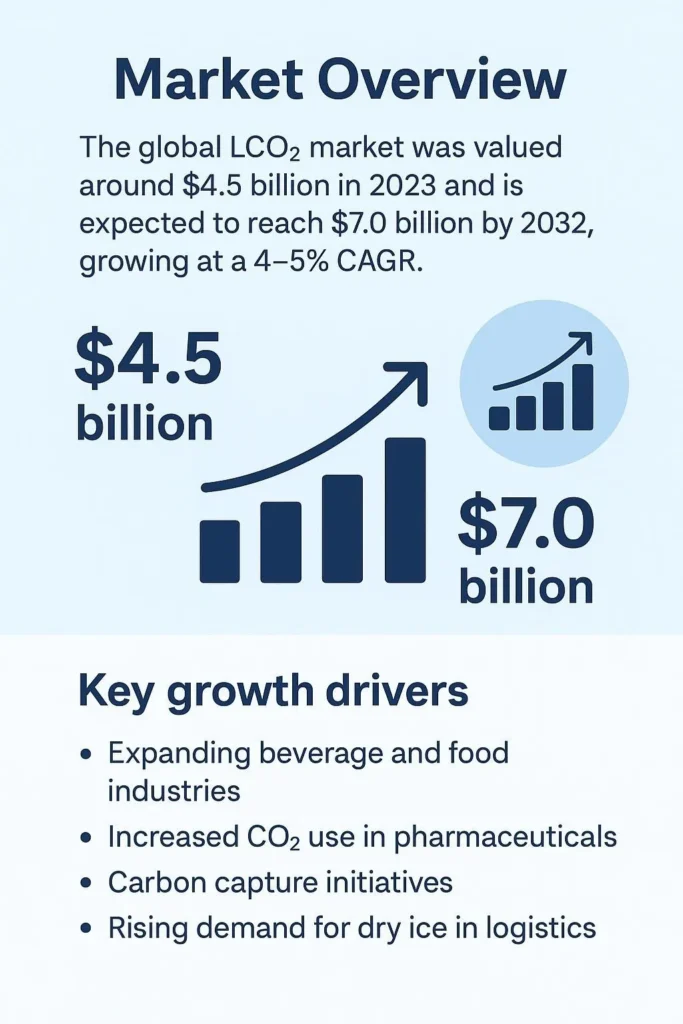

The global LCO? market was valued at around $4.5 billion in 2023 and is expected to reach $7.0 billion by 2032, growing at a 4–5% CAGR.

Key growth drivers:

- Expanding beverage and food industries

- Increased CO? use in pharmaceuticals

- Carbon capture initiatives

- Rising demand for dry ice in logistics

The Asia-Pacific region (particularly China and India) is leading production growth, while North America and Europe remain major consumption markets.

Startup Insights

To succeed, entrepreneurs should:

- Secure a steady CO? source (e.g., brewery or fertilizer plant).

- Ensure high purity (food or medical grade).

- Adhere to safety standards for high-pressure and cryogenic operations.

- Develop distribution networks (tankers or cylinder supply chains).

With the right strategy, a liquid CO? venture can turn industrial waste gas into a profitable and eco-friendly product.

Project Report:- Liquid Carbon Dioxide

2. Tire Recycling Units

Overview

Every year, millions of tires reach the end of their life cycle, creating a serious waste problem. Tire recycling offers a sustainable way to manage this waste while generating valuable byproducts like oil, carbon, and steel.

The most efficient recycling method is pyrolysis, a process that heats shredded tires in the absence of oxygen. The rubber breaks down into gases, oils, and solids—each of which can be reused.

Process Flow

- Shredding: Tires are cut into smaller pieces.

- Heating (Pyrolysis): The rubber is heated in sealed reactors.

- Condensation: Vapors are cooled into pyrolysis oil.

- Collection: Carbon black and steel wire are separated and collected.

Recovered Products

- Pyrolysis Oil: Used as industrial fuel (e.g., in cement kilns and boilers).

- Carbon Black (Char): Sold as a filler for rubber and plastic manufacturing.

- Steel Wire: Recycled by steel producers.

- Crumb Rubber: Used in asphalt, playground flooring, and molded goods.

Market Outlook

The global tire recycling market is growing rapidly, from $9.4 billion in 2024 to an expected $17.9 billion by 2033, at a 4–6% CAGR.

Growth drivers:

- Government mandates for tire recycling

- Rising oil prices (boosting demand for tire-derived fuel)

- Environmental regulations restricting landfill disposal

Countries like India, the U.S., and many in Europe now offer incentives such as subsidies or low-interest loans for recycling startups.

Startup Considerations

To establish a successful tire recycling unit:

- Secure feedstock: Partner with garages, scrapyards, and municipal waste programs.

- Obtain permits: Comply with environmental and emission standards.

- Choose technology: Turnkey pyrolysis systems are available from reliable manufacturers.

- Develop buyer networks: Sell oil, carbon, and steel outputs to industrial users.

With steady tire supply and proper processing, tire recycling offers long-term, sustainable profitability.

Project Report:- WASTE TYRE (TIRE) UTILIZATION

3. Bagasse-Based Biodegradable Tableware

Overview

With single-use plastic bans sweeping across countries, biodegradable tableware made from sugarcane bagasse has emerged as an eco-friendly and lucrative alternative.

Bagasse is the fibrous residue left after sugarcane is crushed for juice. Instead of burning it as waste, it can be molded into plates, bowls, cups, and takeaway containers. These products are compostable, food-safe, and stylish—ideal for restaurants, caterers, and eco-conscious consumers

Project Report:- Bagasse Biodegradable Disposable Tableware.

Manufacturing Process

- Collection & Cleaning: Bagasse is sourced from sugar mills and cleaned.

- Pulping: The fibers are blended with water to create a pulp.

- Molding: The pulp is poured into heated molds and pressed under high temperature and pressure.

- Drying & Finishing: Molded items are dried, trimmed, and sometimes coated for water resistance.

- Quality Check & Packing: Finished products undergo strength and hygiene inspections.

Product Range

- Plates and bowls (various sizes)

- Cups and lids (for hot/cold beverages)

- Takeaway boxes and trays

- Cutlery (spoons, forks, knives)

All these items are 100% compostable, typically decomposing within a few months without polluting the environment.

Market & Growth

The bagasse tableware market is valued at $3.2 billion in 2024 and projected to reach $5.6 billion by 2033, with a 6–7% CAGR.

Growth drivers:

- Bans on single-use plastics

- Corporate sustainability goals

- Expanding sugar industries (ensuring raw material availability)

In Asia-Pacific, especially India, bagasse is abundant and low-cost, making this sector both green and profitable. Many airlines, schools, and event venues have already shifted to bagasse products to meet environmental mandates.

Project Report on:- Bagasse Manufacturing Business

Startup Advantages

- Low-cost raw material: Bagasse is often free or inexpensive.

- High demand: Consumers and businesses prefer biodegradable options.

- Scalable technology: Modular production lines are available.

- Government support: Incentives and procurement policies favor compostable packaging.

This makes bagasse tableware a perfect venture for entrepreneurs entering the sustainable products market.

Related Article on:- Biodegradable Products

Market Forecast and Comparison

| Product | 2024 Market (USD) | 2030s Forecast (USD) | Key Industries |

|---|---|---|---|

| Liquid CO? | ~$4.5 billion | ~$7.0 billion (2032) | Beverages, refrigeration, pharma |

| Tire Recycling | ~$9.4 billion | ~$17.9 billion (2033) | Construction, fuel, rubber |

| Bagasse Tableware | ~$3.2 billion | ~$5.6 billion (2033) | Foodservice, catering, packaging |

All three sectors show strong global demand and align with sustainability trends, including carbon reduction goals and plastic waste bans. Entrepreneurs who invest early in these markets can benefit from long-term regulatory and consumer tailwinds.

How to Evaluate These Projects

Before launching, entrepreneurs should perform a detailed techno-economic feasibility study, covering:

- Raw material sources: (CO? emitters, tire supply chains, bagasse availability)

- Production technology and scale

- Regulatory requirements and certifications

- Market demand and buyers

- Investment cost and ROI projections

Consultants such as Niir Project Consultancy Services (NPCS) offer in-depth reports on manufacturing processes, plant layouts, raw materials, and financials to guide investment decisions.

Conclusion

Sustainable manufacturing is not just an environmental necessity—it’s a business opportunity.

From capturing CO? to recycling waste tires or transforming sugarcane residue into tableware, each venture contributes to a cleaner planet while generating profit.

For entrepreneurs, these industries represent the future of manufacturing—green, circular, and profitable. By combining innovation with environmental stewardship, today’s startups can build tomorrow’s sustainable economy.

Frequently Asked Questions

Q1: What are the main uses of LCO??

LCO? is used for beverage carbonation, food freezing, sterilization, and dry ice production. It’s also used in welding and greenhouse farming for CO? enrichment.

Q2: How does tire recycling create value?

Through pyrolysis, old tires are converted into oil, carbon, and steel—all sellable commodities. The oil replaces industrial fuels, and carbon black is reused in rubber goods.

Q3: Why is bagasse ideal for biodegradable products?

It’s renewable, non-toxic, and fully compostable—unlike plastic or paper alternatives. Using bagasse also prevents open burning and reduces pollution.

Q4: Which sector offers the highest growth?

While tire recycling has the largest market, bagasse tableware offers the fastest growth due to global plastic bans and consumer eco-awareness.

Q5: How can startups get started?

Begin with a feasibility report, secure local raw materials, and explore available subsidies or carbon-credit programs for green manufacturing

How NPCS Can Help You

NPCS (Niir Project Consultancy Services) provides end-to-end support for entrepreneurs, including:

- Detailed Project Reports (DPR).

- Financial modeling & ROI analysis.

- Plant layout & machinery selection.

- Vendor & buyer connect.

- Licensing & compliance guidance.

With expert support, your chances of success in this high-growth sector increase significantly.

Niir Project Consultancy Services

106-E, Kamla Nagar, Opp. Mall ST,

New Delhi-110007, India.

Email: info@entrepreneurindia.co

Mobile: +91-9097075054

Website:https://www.entrepreneurindia.co