The Paper Water Bottles are an innovative and eco-friendly alternative to traditional plastic bottles. As the world becomes more aware of the dangers of plastic pollution, paper-based packaging is emerging as a promising solution. These bottles are typically made from strong paperboard combined with a thin biodegradable or recyclable lining, making them both functional and environmentally responsible. With the rising demand for sustainable packaging, entrepreneurs looking to start Paper Water Bottles Manufacturing Business can tap into a fast-growing and future-ready market.

With global and Indian governments pushing for plastic reduction and consumers actively preferring sustainable products, the paper bottle industry is gaining momentum. For entrepreneurs, this is an opportunity to enter a rapidly growing market while contributing to environmental responsibility. This article explores the market outlook, manufacturing process, investment requirements, government support, and key business strategies.

Contents

Global Market Outlook

The global market for paper bottles is growing at a rapid pace. Early industry estimates valued the paper water bottle market demand at $150–$174 million in the early 2020s. By the early 2030s, projections suggest the market could cross $1–1.5 billion, representing a 20–30% CAGR. Even broader paper-based packaging markets are expanding from $8.5 billion in 2024 to about $22.3 billion in 2033, at ~11% CAGR.

Key Global Growth Drivers

| Driver | Explanation |

|---|---|

| Plastic bans & environmental regulations | Countries like EU members and US states are limiting plastic bottle use, encouraging sustainable packaging. |

| Corporate sustainability goals | Major beverage companies (PepsiCo, Coca-Cola, Carlsberg, Diageo) are investing in paper bottle innovation. |

| Consumer demand | Millennials and Gen-Z prefer products aligned with environmental values. |

| Advances in materials | Better coatings like PLA (biodegradable polymer) are improving leak resistance. |

| Investment in innovation | Startups and packaging manufacturers are building capacity for large-scale production. |

In short, the global market shows consistent double-digit growth, making paper water bottles a future-ready business segment.

Related Article:- Paper Industry

Indian Market Scenario

India is one of the world’s fastest-growing packaging markets. Packaging is the 5th largest sector of the Indian economy and is expanding at 22–25% per year. The overall paper and packaging market in India was about ?7.36 lakh crore (US$84B) in 2024 and is expected to reach ?12.53 lakh crore (US$143B) by 2029.

A segment-specific projection places the paper packaging market at $19.07 billion in 2025, growing to $46.43 billion by 2030 (CAGR ~19.5%).

Factors Driving Growth in India

- Expansion of the e-commerce and FMCG sectors

- Ban on single-use plastics (effective from July 2022)

- Lower GST on paper packaging (reduced to 5%)

- Environmental sustainability is becoming a brand advantage

These conditions make India an ideal environment for paper bottle manufacturing, both for domestic and export markets.

View our:- Books

Export Opportunities

India exported US$3.02 billion worth of paper and paper products in FY 2022–23, according to CAPEXIL. Major export destinations include:

- USA

- UK

- UAE

- Sri Lanka

- Nepal

Global buyers are actively looking for sustainable packaging suppliers, and India’s manufacturing capacity is quickly scaling due to:

- Lower production costs

- Government export incentive schemes such as RoDTEP

- Improved logistics infrastructure

This means Indian paper bottle manufacturers can position themselves as global suppliers, not just domestic sellers.

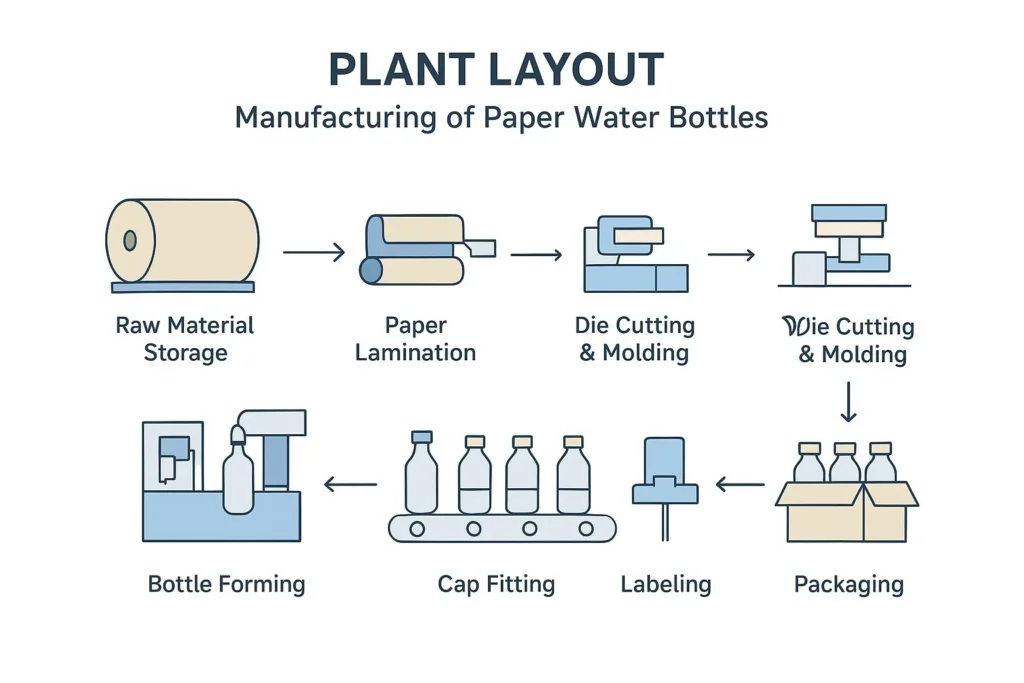

Manufacturing Process Overview

A typical paper water bottle has:

- A paperboard outer shell for strength

- A biodegradable or recyclable inner lining for waterproofing

Core Raw Materials

| Material | Purpose |

|---|---|

| High-quality paperboard or molded fiber | Bottle structure |

| Biodegradable/food-grade polymer (e.g., PLA) | Liquid barrier |

| Adhesives, prints, labels | Branding & sealing |

Required Machinery

- Paper molding or thermoforming machine

- Lamination unit

- Die cutting & shaping machine

- Mold forming / blow molding unit

- Cap fitting & finishing line

For branding, an offset or digital printing line may be included.

View our:- Project Reports

Plant Size & Layout

- Medium-scale plants often start at 3,000–10,000 bottles per day

- A clean, dust-controlled zone is required for food-grade manufacturing

- A dedicated leak & pressure testing lab is essential

Capital Investment

Depending on capacity:

- ?2 crore to ?20+ crore

(Once the scale increases, the unit cost decreases significantly.)

Regulatory Approvals

You will need:

- FSSAI certification (for contact with drinking water)

- ISO 9001 / ISO 14001 (quality & environmental standards)

- Pollution control board approval

For export:

- FDA / EU compliance standards may apply.

Market Demand and Use Cases

Paper bottles are not limited to packaged drinking water. Their application range is wide:

| Category | Use Examples |

|---|---|

| Beverages | Water, flavored drinks, juices |

| Alcoholic beverages | Limited edition eco-friendly packaging |

| Personal care | Shampoo, body wash, lotion |

| Household liquids | Cleaners, detergents |

| Gifting & events | Corporate & hospitality eco Campaigns |

Urban consumers, tourism events, premium beverage brands, and eco-conscious retail chains are early adopters.

Government Support

The government is indirectly supporting the industry through:

- Reduced GST on paper packaging

- Export incentives, including RoDTEP

- Atmanirbhar Bharat manufacturing push

- R&D under CSIR’s National Mission on Sustainable Packaging

Entrepreneurs may also seek MSME loans and subsidy-linked financing under:

- PMEGP

- MUDRA loans

- State industrial investment schemes

Opportunities for Entrepreneurs

| Opportunity | Why It Matters |

|---|---|

| Early mover advantage | Very few domestic manufacturers currently |

| High export demand | Strong interest in the EU, the Middle East, and North America |

| Brand partnerships | FMCG and beverage brands want sustainability solutions |

| Premium pricing | Eco-friendly appeal allows better margins |

| Diversification | Strong interest in EU, the Middle East, and North America |

Challenges to Consider

- Higher cost than plastic (until scaled)

- Requires strong R&D for leak-proof & strength standards

- Consumer education is still in progress in India

- Competition from glass, aluminum, and recyclable plastics

However, these challenges are temporary; scale and material innovation are lowering costs every year.

FAQs

What is the cost of paper bottle manufacturing setup?

The cost of setting up a paper bottle manufacturing unit generally ranges from ?25 lakh to ?1.5 crore, depending on production capacity, machinery type, automation level, land, and raw material requirements.

How to start a paper water bottle business?

To start a paper water bottle business, conduct market research and create a business plan, arrange capital, choose appropriate machinery, set up the production unit, source quality paperboard and linings, obtain necessary licenses, implement quality testing, and build distribution and marketing channels.

How much money is needed to start a water bottle business?

Starting a basic water bottle business may require an investment of ?10 lakh to ?50 lakh for small units. For eco-friendly paper bottle manufacturing with specialized machinery, expect a higher investment of ?25 lakh to ?1.5 crore.

Is the water bottle business profitable?

Yes — the water bottle industry, especially eco-friendly paper bottles, can be profitable due to growing demand and environmental awareness. Typical profit margins range from 20% to 40%, depending on scale, pricing, and distribution efficiency.

Conclusion

Paper water bottle manufacturing is a future-oriented, scalable, and export-friendly business opportunity. Global sustainability trends, India’s booming packaging industry, and government support create a strong foundation for success. Entrepreneurs who invest early in technology, quality, and market positioning can establish leadership in this emerging sector.

If planned carefully—with the right raw materials, plant setup, quality standards, and brand partnerships—a paper bottle manufacturing venture can be both profitable and environmentally meaningful.

How NPCS Can Help You

NPCS (Niir Project Consultancy Services) provides end-to-end support for entrepreneurs, including:

- Detailed Project Reports (DPR).

- Financial modeling & ROI analysis.

- Plant layout & machinery selection.

- Vendor & buyer connect.

- Licensing & compliance guidance.

With expert support, your chances of success in this high-growth sector increase significantly.

Niir Project Consultancy Services

106-E, Kamla Nagar, Opp. Mall ST,

New Delhi-110007, India.

Email: info@entrepreneurindia.co

Mobile: +91-9097075054

Website:https://www.entrepreneurindia.co