Downstream Steel is a Real Manufacturing Opportunity

India’s infrastructure cycle does not involve speculation, but rather execution. Mega-programs like PM GatiShakti and renewable energy expansion projects, metro rail, logistics corridors, industrial parks, and other mega-projects are driving finished Steel consumption to sustained double-digit growth.

The upstream steel industry is capital-intensive and crowded. Downstream Steel Manufacturing offers MSMEs advantages such as faster entry into the market, regional dominance and import substitution. This article breaks down ten downstream steel product manufacturing concepts which are in high demand and that will continue to grow aggressively until 2026.

Contents

- 1 1. Manufacturing of Pre-Engineered Building Structures (PEB).

- 2 2. Solar Module Mounting Structures Manufacturing

- 3 3. Steel Pipes, Tubes & Hollow Sections – ERW / GI /MS

- 4 4. TMT Bars & Construction Steel Products

- 5 5. Steel Fabrication for Metro, Railways & Airports

- 6 6. Steel Wire Products Manufacturing

- 7 7. Steel Service Centers

- 8 8. Stainless Steel Products for Urban Infrastructure

- 9 9. Steel Bolts, Fasteners & High Strength Connectors

- 10 10. Steel Storage Systems & Warehouse Infrastructure

- 11 Learn from India’s Steel Leaders

- 12 Projects for Downstream Steel Manufacturing in 2026

- 13 Conclusion: The brutal truth about downstream steel

- 14 FAQs

1. Manufacturing of Pre-Engineered Building Structures (PEB).

PEB is now the standard for all warehouses, factories, and data centers.

Why is demand structural

- Construction is 40-50% faster than RCC

- Use of massive amounts in airports and metros as well as industrial parks

- Steel consumption is growing (11%+ YoY).

Manufacturing scope

- Columns, purlins and rafters

- Warehouses and industrial sheds

- Cold storage and logistic buildings

Business Logic

- Capex for MSMEs

- EPC-linked recurring orders

- Scalability is easy near the logistic corridors

Outlook for 2026: Demand for e-commerce and warehouse storage will grow By 25-30%

2. Solar Module Mounting Structures Manufacturing

This segment is the most cleanly produced steel segment available today.

Hard facts

- 1 MW = 45 to 55 tonnes of steel

- India’s renewable energy target: 500GW by 2030

- Annual solar addition: 35-40 GW

Products

- Tracker & Fixed MMS

- Channels and angles galvanized

- Solar walkways and cable trays

2026 demand

- 2 to 3 million tonnes of MMS steel per year

Related Article:- 10 Promising and Innovative Startups for Entrepreneurs

3. Steel Pipes, Tubes & Hollow Sections – ERW / GI /MS

India still imports precision and structural pipes. This is both a warning and an opportunity.

Applications

- Water pipelines

- Gas distribution in the city

- Solar plants

- Metro & highway projects

Manufacturable Products

- ERW tubes

- Pipes GI/GL

- Hollow structural sections

Actionable setup

- 20,000-50,000 TPA unit near industrial clusters

4. TMT Bars & Construction Steel Products

Construction consumes 43 % of India’s. This segment is only worth ignoring if you dislike volume businesses.

Products

- TMT bars (Fe500/Fe550).

- Angles, channels, and beams

- Wire rods & steel mesh

Why HTML0 works

- Regional distribution

- Cash cycles that are faster

- Synergy between Induction furnace and rolling mill

Project idea

- Rolling mill for TMT with billet integration – 50,000 TPA

5. Steel Fabrication for Metro, Railways & Airports

India has implemented, not planned, the expansion of airports, railways, and metro Phase-II.

Fabricated Products

- Foot-over-bridges

- Station canopies

- The depot sheds

- Terminal Structures

Why MSMEs Win

- Capex moderate

- EPC Subcontracting Model

- Order visibility backed by the government

Growth Outlook: 20% growth rate through 2026

View:- Project Report

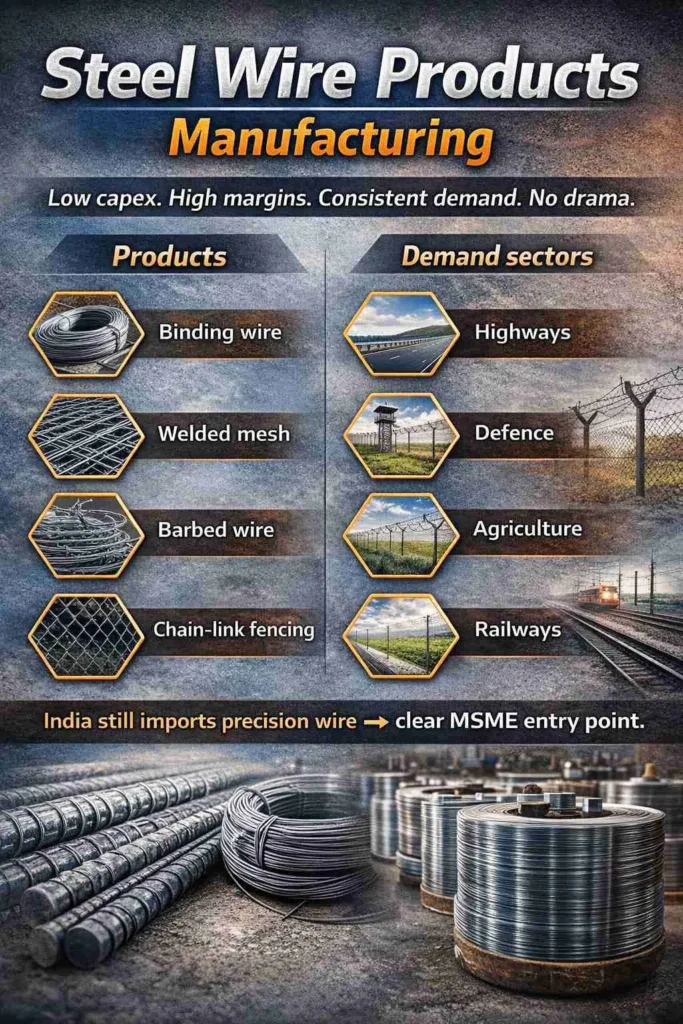

6. Steel Wire Products Manufacturing

Low capital expenditure. High margins. Consistent demand. No drama.

Products

- Binding wire

- Welded mesh

- Barbed wire

- Chain-link fencing

Demand sectors

- Highways

- Defence

- Agriculture

- Railways

Clear entry point for MSME.

7. Steel Service Centers

Smart entrepreneurs are focusing on this value-adding method that does not involve melting steel.

Services

- Cut-to-length sheets

- Slitted coils

- Precision flat steel

End users

- Electric vehicle manufacturers

- Engineering units

- EPCs for Renewable Energy

2026-ready idea

- Decoiler + slitting line near auto/industrial belts

8. Stainless Steel Products for Urban Infrastructure

In India, urban areas are switching from mild steel to stainless for hygiene and durability.

Products

- SS railings

- Hospital Furniture

- Metro interiors

- Commercial kitchen equipment

Why HTML0 works

- High Finish = Higher Margins

- Domestic + export demand

- Scalability driven by CNC + polishing

9. Steel Bolts, Fasteners & High Strength Connectors

Fasteners are used in every infrastructure project.

Products

- HSFG bolts

- Anchor bolts

- Solar MMS clamps

- Rail fasteners

Strategic edge

- Import substitution

- Add hot-dip galvanizing to margin control

View our:- Books

10. Steel Storage Systems & Warehouse Infrastructure

The demand for warehousing is growing across FMCG and ecommerce.

Products

- Pallet racks

- Mezzanine floors

- Mobile racking systems

- Industrial Shelving

Market reality

- India needs to build 25 million sq. The segment is both scalable and practical.

Learn from India’s Steel Leaders

- Tata Steel: Sustainability, long-term thinking, and technology

- JSW Steel: speed, modernization, and scale

- ArcelorMittal: Global strategy and consolidation

Common thread? Execution is more important than optimism.

Projects for Downstream Steel Manufacturing in 2026

- Automated Steel Service Center

- High-speed ERW pipe mill

- Solar MMS Manufacturing Cluster

- Railway Fabrication Unit

- Sheet line coated with GI/GL

- Storage racks

- Fastener galvanizing unit

- SS metro interior components

- Steel logistics systems

- Regional PEB Manufacturing Hub

Conclusion: The brutal truth about downstream steel

This is not an industry where you can “get rich fast”. This is a stay disciplined to get rich sector.

You can:

- Respect for the law

- Build volume-first economics

- Choose demand-backed products

- Keep an eye on EPC and Infrastructure Execution

Over the next 5 to 7 years, downstream steel manufacturing will pay you more than other industrial segments.

This is the place to look for serious manufacturers if you are looking for stability, scalability and growth that aligns with policy.

Watch:- Youtube Channel

How NPCS Can Help

NPCS (Niir Project Consultancy Services) provides end-to-end support for entrepreneurs, including:

- Detailed Project Reports (DPR).

- Financial modeling & ROI analysis.

- Plant layout & machinery selection.

- Vendor & buyer connect.

- Licensing & compliance guidance.

With expert support, your chances of success in this high-growth sector increase significantly.

Niir Project Consultancy Services

106-E, Kamla Nagar, Opp. Mall ST,

New Delhi-110007, India.

Email: info@entrepreneurindia.co

Mobile: +91-9097075054

Website:https://www.entrepreneurindia.co

FAQs

What are downstream steel products?

Value-added steel products like PEB structures, pipes, solar MMS, fasteners, fabrication, wire products, and storage systems made from finished steel.

Is downstream steel manufacturing profitable in India?

Yes—if you choose infrastructure-linked products and operate at the right scale. Profit comes from volume, location, and EPC linkage, not speculation.

Which downstream steel products are in highest demand (2025–26)?

PEB structures, solar MMS, steel pipes & tubes, TMT bars, and warehouse racking systems.

Is this suitable for MSMEs?

Yes. Most downstream steel segments are MSME-friendly with modular expansion and strong domestic demand.

What are the main risks?

Wrong product choice, overcapacity, poor location, and weak demand assessment.