New Manufacturing Business Opportunities in India

India has entered a critical phase of its industrial evolution. Manufacturing is no longer an unstructured growth opportunity, but a well-structured one, thanks to policy reforms and global supply-chain realignments. Government initiatives like Make in India, Atmanirbhar Bharat and China+1 strategy push capital, technology and demand towards domestic manufacturing.

This shift was reinforced by the Union Budget 2024-25, which included infrastructure expansion, MSME support, simplified compliance and a long-term R&D financing program of Rs 1 lakh crore. This environment is a rare opportunity for entrepreneurs and MSMEs: strong domestic demand and rising exports, as well as policy-backed reduction of risk. Here are the most promising manufacturing business opportunities that startups in India can enter and scale.

Contents

- 0.1 1. Defence Component Manufacturing

- 0.2 2. Electric Vehicle (EV), Components, and Battery Packs

- 0.3 3. Green Hydrogen and Renewable Energy Equipment

- 0.4 4. Aerospace and Drone Manufacturing

- 0.5 5. Electronics and Semiconductor Hardware

- 0.6 6. Pharmaceutical APIs and medical devices

- 0.7 7. Specialty Chemicals and Advanced Materials

- 0.8 8. Recycling and Waste-Based Production

- 0.9 9. Food Processing and Agro-based Manufacturing

- 0.10 10. Industrial Automation, Robotics & Smart Factory Equipment Manufacturing

- 0.11 The conclusion of the article is:

- 0.12 How NPCS Can Help

- 1 FAQs – Industrial Automation & Robotics Manufacturing in India

1. Defence Component Manufacturing

India spends more on defence than any other country in the world, but import dependency is still high. The government has made defence manufacturing available to MSMEs and private companies in order to close the gap. The government’s long-term contracts, R&D grant, and offset policy have led to a sustained demand for precision parts, electronics, drone parts, and subsystems.

Startups can enter through niche manufacturing–machined components, avionics parts, protective equipment, or electronic modules–by supplying to larger OEMs. Defence manufacturing rewards compliance and quality, not price wars. This makes it a great place for entrepreneurs who are disciplined.

2. Electric Vehicle (EV), Components, and Battery Packs

The adoption of electric vehicles is increasing across all fleets, including two-wheelers and three-wheelers. India imports the majority of EV components and especially lithium-ion battery packs. This gap presents opportunities for battery pack assembly and thermal systems as well as motor controllers, charging devices, thermal systems, EV electronics, and charging equipment.

Even small manufacturers can get into the industry by localising a component that is import-dependent. Early movers in EV manufacturing are more likely to build strong supply relationships than consumer brands.

Related Article:- Indian Startups

3. Green Hydrogen and Renewable Energy Equipment

India’s renewable-energy targets are driving massive demand in solar modules, wind turbine components, and grid-scale storage systems. Import duties, production incentives, and other measures now encourage domestic manufacturing of solar components and mounting structures.

Early manufacturers have the opportunity to build electrolyzers and storage tanks as well as fuel-cell components. This sector is a good investment, has export potential and aligns with the long-term energy policies.

4. Aerospace and Drone Manufacturing

Drone production has evolved from a limited activity to one that is a strategic priority. Import bans have led to a strong demand for drones and parts made in the country.

MSMEs are able to manufacture assemblies, airframes or motors with relatively modest capital. Aerospace manufacturing has a high value and low volume, so it is suitable for startups that have engineering skills and a quality-driven approach.

View:- Project Report

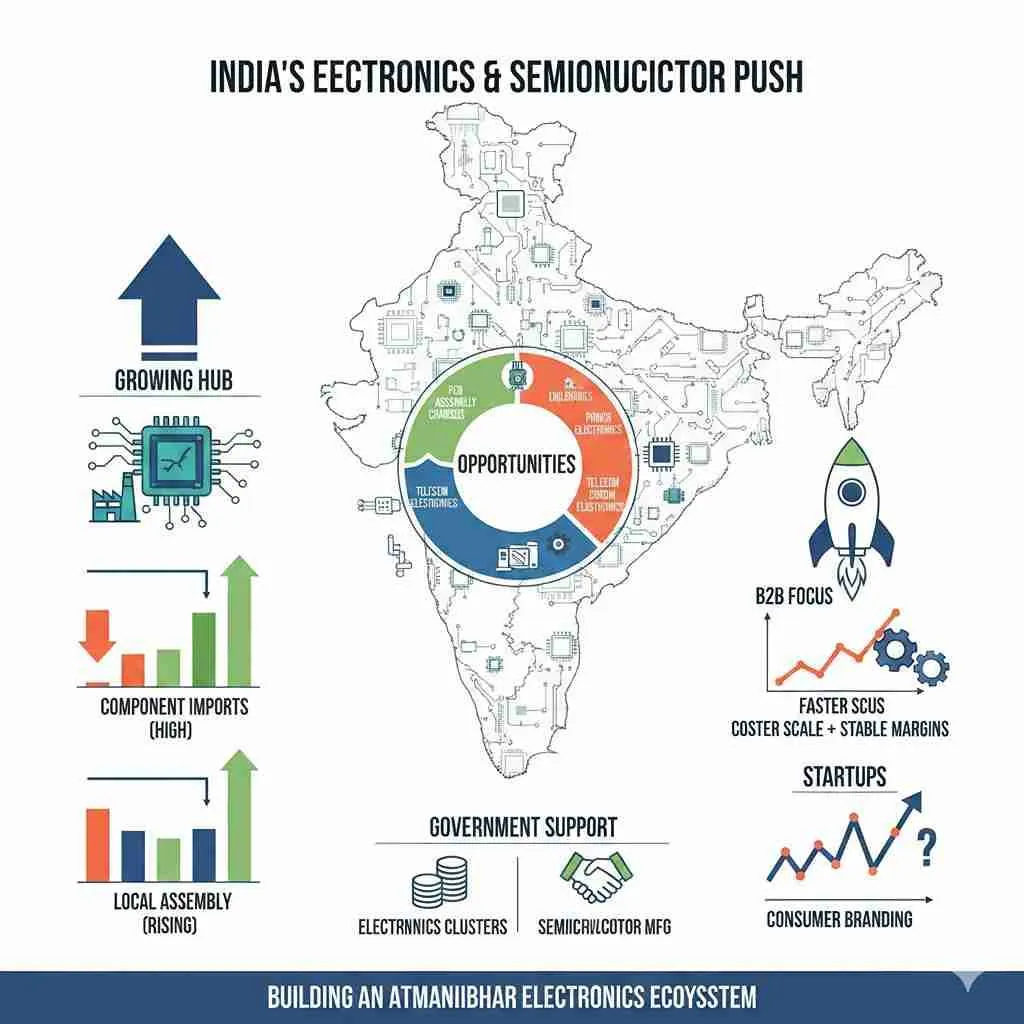

5. Electronics and Semiconductor Hardware

India is quickly becoming a global hub for electronics manufacturing, but component imports are still high. There are opportunities in PCB assembly and chargers. Enclosures, power electronic, telecom equipment, industrial electronics, and enclosures.

Government incentives are now supporting electronics clusters, component assembly, and semiconductor manufacturing. Startups who focus on B2B rather than consumer branding can scale faster and with stable margins.

6. Pharmaceutical APIs and medical devices

India’s strength in pharmaceuticals is offset by its high import dependency on APIs and equipment for medical use. The government-backed bulk drug park and medical device clusters have now reduced entry barriers.

Export potential and long-term demand are available for manufacturing APIs, intermediates or diagnostic kits. The compliance is strict but the margins increase with certification and scale.

View our:- Books

7. Specialty Chemicals and Advanced Materials

Specialty chemicals are a high-value manufacturing opportunity. Rapid growth is supported by import substitution, global diversification, and strong export demands.

Startups can concentrate on niche chemicals, additives or coatings. They can also focus on electronic-grade materials or advanced composites. This sector rewards technical expertise and consistency in process over marketing spending.

8. Recycling and Waste-Based Production

India’s drive towards a circular economic system is creating a demand for manufacturing based on recycling. E-waste recycling, battery recycling and plastic reprocessing are now regulated.

Recycling units are able to benefit from a stable raw material supply and green financing. They also enjoy a long-term industrial demand. When executed in large scale, this sector can combine sustainability and profitability.

9. Food Processing and Agro-based Manufacturing

India only processes a small fraction of its agricultural production, leaving a huge amount of value untapped. There are many manufacturing opportunities in packaged food, dairy processing and grains.

Food processing is a scalable, stable manufacturing business, provided that hygiene, quality and distribution are professionally handled.

10. Industrial Automation, Robotics & Smart Factory Equipment Manufacturing

Industrial Automation and Robotics Manufacturing is a high-potential opportunity as Indian factories are rapidly automating to cut costs and meet quality standards. Demand is rising for PLC panels, conveyors, sensors, robotic arms, and retrofit automation kits. Heavy import dependence and the growth of EV, pharma, electronics, and food plants make this a stable, long-term B2B manufacturing business with recurring service revenue.

Watch:- Youtube Channel

The conclusion of the article is:

India’s manufacturing industry is undergoing structural change. Defence, EVs and renewables, electronics, pharmaceuticals, chemicals, food processing, and recycling are no longer just speculative concepts. They are now policy-backed growth drivers.

Entrepreneurs can gain a competitive advantage by focusing on a single manufacturing niche and building technical capabilities, aligning themselves with government incentives, rather than following trends. Today, manufacturing rewards those who are disciplined, compliant, and execute their plans, not those who take shortcuts.

The window of opportunity is now open. The next generation of Indian manufacturing will be defined by those who act early, plan well, and invest with confidence.

Find the Best Idea for Yourself With our Startup Selector To

How NPCS Can Help

NPCS (Niir Project Consultancy Services) provides end-to-end support for entrepreneurs, including:

- Detailed Project Reports (DPR).

- Financial modelling & ROI analysis.

- Plant layout & machinery selection.

- Vendor & buyer connect.

- Licensing & compliance guidance.

With expert support, your chances of success in this high-growth sector increase significantly.

Niir Project Consultancy Services

106-E, Kamla Nagar, Opp. Mall ST,

New Delhi-110007, India.

Email: info@entrepreneurindia.co

Mobile: +91-9097075054

Website:https://www.entrepreneurindia.co

FAQs – Industrial Automation & Robotics Manufacturing in India

Q1. Is industrial automation manufacturing profitable in India?

Yes. Demand is driven by EV, pharma, electronics, food, and logistics sectors, with high margins in system integration, customization, and after-sales service.

Q2. What products can MSMEs manufacture in industrial automation?

PLC control panels, conveyors, material-handling systems, sensors, robotic arms, packaging machines, and automation retrofit kits.

Q3. Is this business capital-intensive?

Moderate. Entry is possible with system integration and panel manufacturing before scaling into full robotic or equipment manufacturing.

Q4. Why is automation demand increasing in India?

Rising labor costs, quality compliance, export requirements, and Industry 4.0 adoption are forcing factories to automate.

Q5. Are there government incentives for automation manufacturing?

Yes. MSME credit guarantees, capital equipment subsidies, electronics cluster support, and Industry 4.0 initiatives apply.