Contents

- 1 Market Demand Drivers: Infrastructure Supports Manufacturing

- 2 Understanding the Product Segments

- 3 Manufacturing Process: Engineering Discipline Over Complication

- 4 Machinery Needed in MSME Manufacturing Units

- 5 Investment Logic and Profitability Factors

- 6 Export Opportunities, Global Demand

- 7 Strategic Lessons of Indian Industrial Leaders

- 8 Emerging MSME Project Opportunities

- 9 Risk Factors and Managing Strategies

- 10 Conclusion: A Future-Proof Manufacturing Opportunity

- 11 Frequently Asked Questions (FAQ)

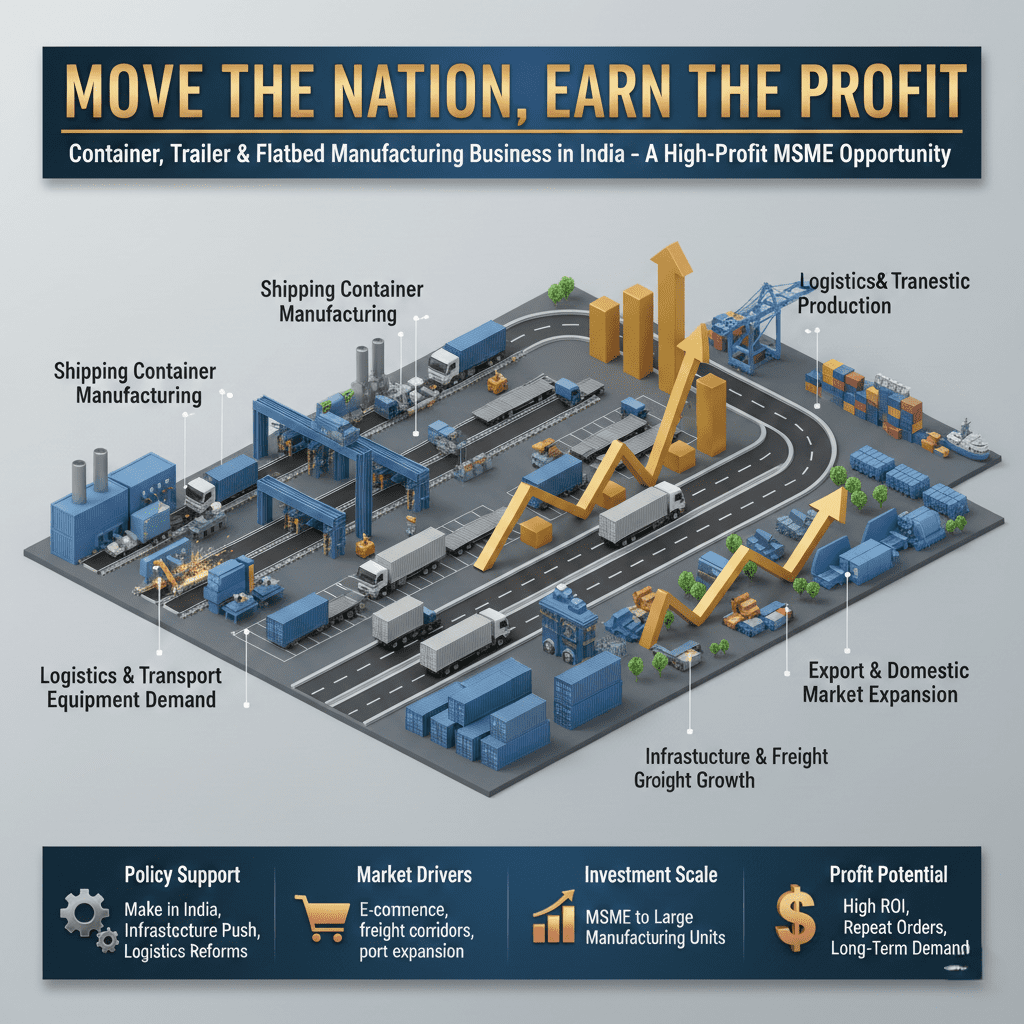

Introduction: Container manufacturing business in India

In the logistics industry, profits are rarely made during the actual transportation process – they are made in the interface between goods being transported from road to rail, from rail to port, and from inland waterways to port. Containers, trailers and flatbeds are the backbone of these transitions as they allow for seamless cargo movement whilst reducing delays and handling costs.

For MSME entrepreneurs and industrial investors, intermodal equipment manufacturing is a rare combination of stability and scalability. The advanced transportation equipment requirements of India increase as the country develops new freight corridors and multimodal logistics parks and export facilities. The industry functions according to permanent structural requirements because goods movement will always exist and organizations will continuously need equipment for their operations.

This article delves into manufacturing opportunities, market potential, investment logic, processes and risks – to help entrepreneurs understand why containers, trailers and flatbeds are becoming strategic industrial investments.(Container manufacturing business in India)

Read More: Profitable Agro Based Projects with Project Profiles (Cereal Food Technology) (2nd Revised Edition)

Market Demand Drivers: Infrastructure Supports Manufacturing

India’s logistics ecosystem is in a process of structural transformation. Government initiatives like dedicated freight corridors, port modernization, inland waterways development and industrial corridors are adding a lot of capacity to the freight.(Container manufacturing business in India)

For every kilometer of new freight infrastructure there is demand for transport equipment. As freight volume increases, logistics operators enlarge fleets, upgrade aging assets and invest in specialized equipment. This produces a strong feedback loop:

- Infrastructure investment helps to increase freight movement

- Higher freight volumes mean higher utilization of equipment

- Utilization increases the rate of replacement

- Manufacturing demand increases steadily

For the MSME manufacturers, this translates to long-term institutional demand as opposed to fragmented retail buyers. The logistics companies together with EPC contractors and exporters and industrial fleet operators establish themselves as returning clients who generate steady income for the business.

Understanding the Product Segments

1. Containers: Standardized Worldwide Assets

Containers are the basis of modern intermodal logistics. ISO containers, high-cube containers, refrigerants, and specialized cargo boxes exist as worldwide standards which allow for simple international trade operations.

Container manufacturing demands financial resources for steel production and stringent quality assessment procedures, yet standardization enables manufacturing at scale and international trade capabilities. With global supply chains looking for diversification in sourcing outside of traditional hubs, Indian manufacturers are having a growing export potential.(Container manufacturing business in India)

2. Trailers: Volume Domestic Opportunity

Trailers are the link between the infrastructure and flexible road transportation. Skeletal trailers, container carriers & multi-axle logistics trailers are experiencing a high demand with the increasing e-commerce and industrial production and freight mobility.

For MSMEs, trailer manufacturing is often the easiest gateway to get into the market because it can have relatively lower CAPEX and can offer faster order cycles. Fleet operators often expand and upgrade trailers, which assures repeat business.

Read More: Profitable Small Scale Industries- Money making Business Ideas for Startup (when you don’t know what industry to start)-2nd Revised Edition

3. Flatbeds: Customisation with Increased Margins

Flatbeds function as transportation platforms which carry oversized goods that include machinery and steel structures and infrastructure components. The production of flatbeds results in fewer total units compared to trailers yet flatbeds generate higher profits because of their requirement for custom engineering work and their specific load handling methods.(Container manufacturing business in India)

Together, these products constitute an interrelated manufacturing ecosystem that shares manufacturing infrastructure and engineering capabilities.

Manufacturing Process: Engineering Discipline Over Complication

Intermodal equipment manufacturing is not as much about innovation, but more about precision and process discipline. The manufacturing workflow usually consists of:

- Cutting steel plates and profiles on CNC plasma or laser machines

- Forming structural elements using hydraulic presses and roll forming

- Welding using Heavy Fabrication Techniques with Fixtures and Manulators

- Structural assembly using jigs to ensure dimensional accuracy

- Surface treatment – shot blasting and Corrosion resistant coating

- Final assembly and quality testing

Success relies greatly on the quality of the weld, the load distribution, the alignment of the axles and the durability of the coating. Plants focusing on process consistency are beating those investing heavily in unnecessary automation.

Read More: Handbook on Steel Bars, Wires, Tubes, Pipes, S.S. Sheets Production with Ferrous Metal Casting & Processing

Machinery Needed in MSME Manufacturing Units

Typical key equipment includes:

- CNC plasma or laser cutting machine for steel processing

- Hydraulic presses and roll forming machines

- Heavy welding set and fabrication fixtures

- Shot blasting lines, industrial painting lines

- Overheads and material handling equipment

Instead of investing in cosmetic automation, MSMEs should prioritize machines that provide a better tolerance accuracy, throughput and production efficiency.(Container manufacturing business in India)

Investment Logic and Profitability Factors

Consultants are assessing intermodal manufacturing projects based on asset productivity and not simply profit margin. Important metrics include:

- Output per fabrication bay

- Equipment utilization rates

- Steel yield & scrap management

- Working capital cycle with logistics buyers

- After-sales services e.g. repair and refurbishment

Manufacturers who integrate production with lifecycle services are often able to have better long-term cash flows. Refurbishment and retrofit services create recurring revenue and better customer retention.(Container manufacturing business in India)

Read More: Steel Containers: Key Role of Cargo Containers in Global Trade

Export Opportunities, Global Demand

Transport equipment is internationally traded with a good export potential. The Indian manufacturers can target:

- International logistics fleet

- Coastal shipping operators

- EPC Contractors carrying out overseas infrastructure projects

- Markets in Africa, South East Asia and the Middle East

Export participation does not always entail shipping full vehicles. Components, sub-assemblies and knock-down kits are possible entry strategies that minimize the complexity of logistics and open up global revenue streams.

Strategic Lessons of Indian Industrial Leaders

The transport manufacturers in India offer valuable insights:

- Tata Motors, put a focus to design the products not on technical specification, but to the operational use of the vehicle.

- Ashok Leyland developed robust fleet-centric service networks, which demonstrated that lifecycle value is more important than upfront pricing.

- Larsen & Toubro combined heavy engineering and infrastructure projects, proving the concept of how manufacturing increase relates to the growth of the nation.

Intermodal equipment manufacturing employs similar strategic principles — durability, scalability and customer-focused engineering.(Container manufacturing business in India)

Emerging MSME Project Opportunities

Multiple project structures can be considered by the entrepreneur:

- Manufacturing units for container export oriented scalability

- Trailer and skeletal carrier manufacturing (capital investment is low)

- Flatbed and project cargo equipment manufacturing for high margin customization

- Integrated intermodal equipment plants from common fabrication infrastructure

Phased investment strategies enable MSMEs to start small and increase production in response to the growing market demand.(Container manufacturing business in India)

Read More: How to Start a Steel Shipping Container Manufacturing Business in India – Cost, Investment, Profit & Market Demand

Risk Factors and Managing Strategies

Like any heavy engineering industry, intermodal manufacturing has risks such as:

- Steel price fluctuations

- Freight demand cyclicality

- Buyer concentration

- Compliance with changing transport regulations

These risks can be reduced by diversified product portfolios, phased capacity expansion, participation in the export market, and good financial planning.(Container manufacturing business in India)

Conclusion: A Future-Proof Manufacturing Opportunity

The industrial sector requires containers and trailers and flatbeds as vital components to maintain international trade and logistics operations. The development of India’s multimodal transport infrastructure creates permanent asset-based business opportunities for MSMEs which operate in intermodal equipment manufacturing.

The establishment of engineering-based lifecycle services and scalable manufacturing strategies enables entrepreneurs to access a market that benefits from infrastructure development and industrial growth and international trade expansion.(Container manufacturing business in India)

Frequently Asked Questions (FAQ)

Q1. Is intermodal equipment manufacturing suitable for MSMEs?

Yes. Trailer and flatbed manufacturing offer relatively lower CAPEX and allow phased expansion, making them suitable for MSMEs and first-generation entrepreneurs.

Q2. Which segment offers the fastest break-even period?

Trailers and flatbeds usually provide faster break-even due to shorter production cycles and strong domestic demand.

Q3. Is export necessary for profitability?

No, but export markets enhance scalability, diversify risk, and increase revenue opportunities.

Q4. How important is factory location?

Location is critical. Proximity to steel suppliers, industrial clusters, freight corridors, and ports improves logistics efficiency and reduces costs.

Q5. Can manufacturers expand into services later?

Yes. Repair, refurbishment, and retrofit services significantly improve long-term profitability and customer retention.

Q6. What skills are required to start such a business?

Strong fabrication knowledge, engineering design capabilities, quality control systems, and supply chain management skills are essential.