High growth chemical business, plant consultants, and industrial buyers for long enough and one truth becomes obvious. In the chemical manufacturing industry, demand is never a guarantee of success. Many projects with strong market demand fail as feasibility assumptions, working capital requirements, quality consistency, or compliance costs are under-estimated.

The chemical and petrochemical industry is therefore attracting first-generation entrepreneurs who are willing to build systematically and not chase trends. The quiet power of chemicals in agriculture, pharmaceuticals, packaging, automobiles, construction, textiles, paints, detergents and infrastructure. This multi-sector dependence gives them a stability that is hard to match for other manufacturing industries.

Contents

- 1 Why the Time Is Right for New Chemical Manufacturing Ventures

- 2 How First Time Entrepreneurs Should Choose the Right Chemical Project

- 3 Specialty Chemical Blends & Performance Additives

- 4 Polymer Processing Inputs & Plastic Intermediates

- 5 Formulation Based Agrochemicals and Cleaning Chemicals in the Industrial World

- 6 Water Treatment and Chlor-Alkali Downstream Chemicals

- 7 Rubber and Elastomer Compounding Inputs

- 8 Why Industrial Clusters Are More Important than Product Choice

- 9 Learning from Established Industry Builders

- 10 How Niir Project Consultancy Services (NPCS) Supports First Time Entrepreneurs

- 11 Closing Note

- 12 Frequently Asked Questions (FAQs)

Why the Time Is Right for New Chemical Manufacturing Ventures

Chemical manufacturing currently enjoys structural demand but not speculation. High capacity utilization across multiple segments suggests that buyers are actively sourcing in an effort to keep their operations running, not on an experiment basis with new suppliers. When downstream manufacturers have strong utilization, it is by design that they have alternative vendors to mitigate the company’s supply risk.

Among the signals that are important to new entrepreneurs are three:

- Demand is already created and replicable

- Dependency of buyers on reliable suppliers is growing

- The ecosystem backs MSME participation by means of skilled manpower, vendors and logistics

Together, these things make chemical manufacturing a lot more accessible than it was ten years ago.(high growth chemical business)

How First Time Entrepreneurs Should Choose the Right Chemical Project

Many first-time founders decide what to found based on popularity or short-term margins. Both approaches may be dangerous. Popular products face intense competition among their prices and niche high-margin products are often accompanied by complicated buyer approvals and regulatory hurdles.

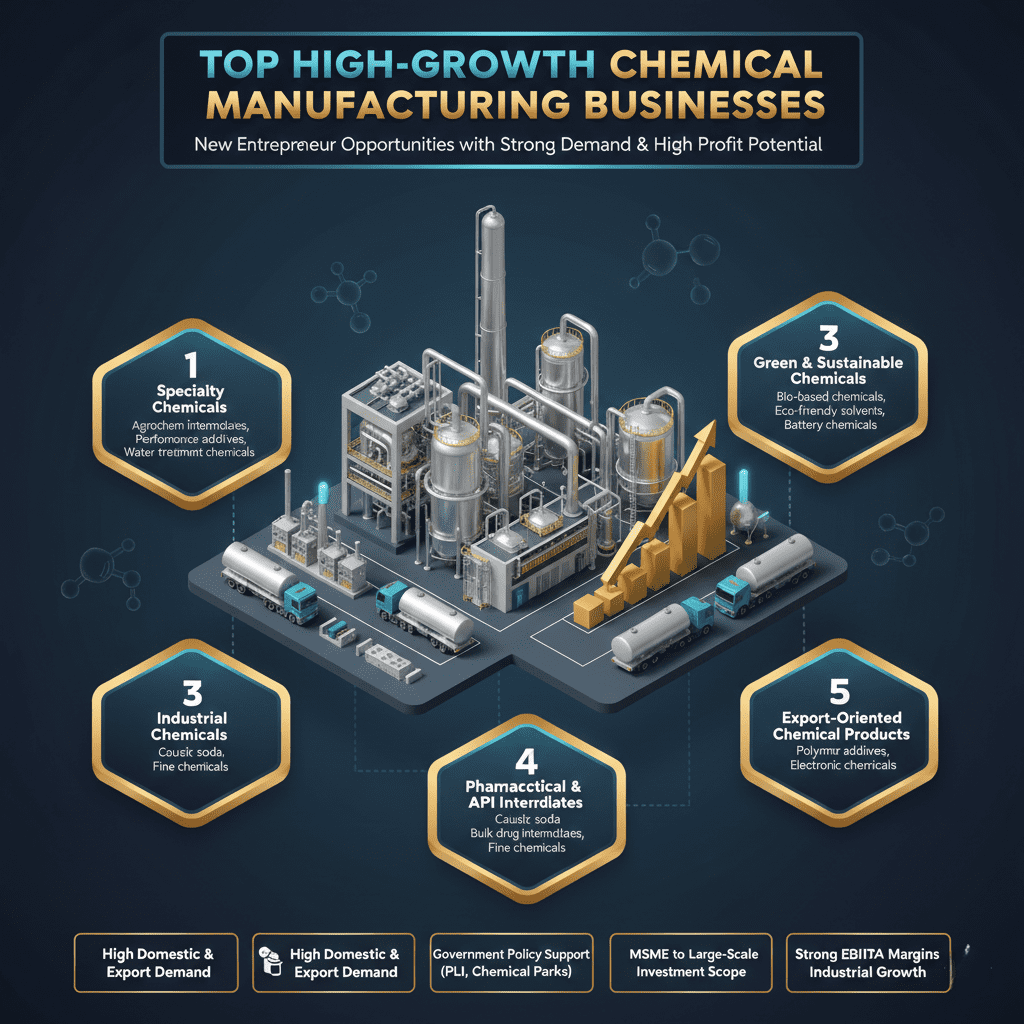

The typical common features of high-growth chemical projects are five in number:

- Raw materials are available through transparent and stable supply channels

- Product quality can be ensured in a reliable process control

- Cash cycles are predictable and do not tie up capital in receivables or inventory

- Capacity can be added in stages without redesigning the entire plant

- Environmental and safety compliance is manageable at MSME scale

Projects that meet these criteria require some discipline and patience over time.(high growth chemical business)

Specialty Chemical Blends & Performance Additives

Specialty chemical blends are among the best entrepreneur-friendly breaks into chemical manufacturing. These products are widely used in plastics, rubber, paint, coating, adhesive, construction chemicals and textile process. Buyers in these industries do not really buy on price alone. Instead, they appreciate consistency, stability of shelf life and technical reliability.

The primary reasons that make this segment scalable for first-time founders are:

- Strong repeat ordering once a formulation is approved

- High stickiness of suppliers as a result of process dependency at the customer end

- Scalability by means of additional blending capacity, not heavy capex

Margins come in specialty blends from formulation discipline and quality assurance, not from commodity pricing power.(high growth chemical business)

Read More: Industrial Chemicals Technology Hand Book

Polymer Processing Inputs & Plastic Intermediates

The petrochemical value chain is massive, but first-time entrepreneurs are better placed at the downstream end, as opposed to the capital-intensive upstream end. Polymer processing inputs and intermediates permit participation in large volume markets without excessive financial risk.

This segment usually consists of:

- Special compounds of polymer for automotive and electrical applications

- Additive masterbatches – Colour and additive masterbatches

- Reinforced grades or flame-retardant grades of polymers

- Moulding Compounds Used by OEMs and Ancillaries

Due to the standard specifications and good shelf life of polymer-based products, they also provide a natural path for exports once quality systems are instituted.(high growth chemical business)

Formulation Based Agrochemicals and Cleaning Chemicals in the Industrial World

Formulation-led chemical businesses enable manufacturers to develop both production and market. The cycles of agrochemical formulations are seasonal, but are predictable and repeated year after year. Under the conservative management of inventory levels and receivables, profitability improves considerably.

Industrial and institutional cleaning chemicals are used in factories, hospitals, hotels, food plants and logistics centres. Buyers in this segment often have a preference for long-term supply relationships which leads to stable demand and healthier cash flows.

Some of the most important operational advantages in formulation businesses include:

- Lower capital intensity than bulk chemical manufacturing

- Ability to differentiate through packaging, branding and service

- Repeat demand driven by consumption not one-time projects

Water Treatment and Chlor-Alkali Downstream Chemicals

While chlor-alkali production itself requires heavy investment, the downstream ecosystem offers a number of MSME friendly opportunities. Water treatment chemicals, effluent treatment formulations, pH control products and industrial salts are ongoing requirements for consumption because of regulatory and operational requirements.

This segment is increasing steadily because:

- Demand is based on compliance and not trends in the market

- Industrial buyers do not prefer frequent change of suppliers

- Quality consistency is more important than lowest price

As a result of this, disciplined manufacturers benefit from long term customer retention.(high growth chemical business)

Rubber and Elastomer Compounding Inputs

Rubber and elastomer compounding falls somewhere between design technical complexity and production scale. Automotive parts, industrial hoses, belts, gaskets, and footwear manufacturers rely on the uniformity of compounding materials.

A common growth path for this segment includes:

- Starting off with a small range of products

- Qualifying with Local OEMs or Ancillary Units

- Expanding of SKUs after process stabilization

- Strengthening lab and testing capability

- Gradually entering into export markets

This step-by-step expansion helps to control the risk, while building credibility.(high growth chemical business)

Why Industrial Clusters Are More Important than Product Choice

Chemical manufacturing almost never works alone. Plants function more efficiently when they are part of a larger industrial ecosystem. Chemical parks and industrial clusters offer common utilities, waste treatment facilities, logistics facilities, and a pool of skilled manpower that are ready for employment.

For the first-time entrepreneurs, cluster-based locations help to reduce:

- Delay in approval and compliance

- Utility reliability issues

- Raw material and dispatch logistics cost

- Early stage operational uncertainty

In many cases, location strategy is as much a determinant of success as the choice of product.(high growth chemical business)

Learning from Established Industry Builders

Several well known industrial leaders started with small operations. Their success was not due to scale alone, but rather to disciplined execution. Karsan Bhai Patel was focused on cost and efficiency of distribution. Chandrakant Gorgi – showed us how moving from commodity products into specialty chemistry creates stable value. Ashok Chaturvedi demonstrated how consistency and quality systems can adapt packaging and polymer processing methods into technology-led businesses.

The common lesson is fairly simple: Growth follows systems, not short cuts.(high growth chemical business)

How Niir Project Consultancy Services (NPCS) Supports First Time Entrepreneurs

High-growth chemical projects can only be successful if assumptions of feasibility are realistic. Many failures have come back to underestimated utility costs, inaccurate yield assumptions, overlooked compliance costs, or aggressive working capital planning.

NPCS offers support to entrepreneurs in the form of structured techno-economic feasibility studies that cover:

- Demand assessment for the market and product selection

- Manufacturing process understanding & capacity planning

- Machinery, utilities and raw material analysis

- Financial modelling and profitability analysis

This way, founders can invest with clarity using their investment rather than optimism.(high growth chemical business)

Closing Note

A successful chemical manufacturing business is not created by chasing trending products. It is constructed by choosing repeatable demand, designing the ability for compliance into the plant, maintaining cash cycles judiciously, and incrementally adding capacity. When approached with discipline, chemical manufacturing is one of the most resilient and scalable paths for first generation entrepreneurs.(high growth chemical business)

Frequently Asked Questions (FAQs)

Which Chemical Projects Are Safest for Beginners?

Formulation and blending based projects are generally safer because of reduced capital requirements, modular scaling and manageable compliances.

What makes a high growth chemical project?

The organization depends on three main elements which include its ability to obtain repeat industrial orders and its possession of stable margins that remain intact during commodity price fluctuations and its capability to expand production capacity without incurring substantial fixed cost increases.

Small chemical units possess the capability to export their manufactured products?

Yes. Products with standardized specifications, quality and documentation have a high chance of finding export buyers once credibility is established.

What are the biggest new chemical entrepreneurs mistakes?

Poor working capital control, inconsistent quality, poor EHS compliance and adding new products before stabilising the core business.

Is it really necessary to start from inside an industrial cluster for it?

While not required, cluster-based locations greatly reduce the infrastructure burden, make compliance easier and enhance operational reliability.(high growth chemical business)