Contents

- 1 The Concept of Ports Based Manufacturing Clusters

- 2 Why Steel Manufacturing is the Perfect fit for Port Locations

- 3 Demand Stability through Institutional Buyers

- 4 Steel Product Segments Most Suitable for Port Clusters

- 4.1 Read More: Handbook on Steel Bars, Wires, Tubes, Pipes, S.S. Sheets Production with Ferrous Metal Casting & Processing

- 4.2 Container and Container Component Production

- 4.3 Marine and Port Infrastructure Fabrication

- 4.4 Structural Steel for Export Projects

- 4.5 Manufacturing of Logistics Equipment

- 4.6 Read More: Top 20 Steel Manufacturing Business Ideas

- 5 Economic Benefits and Profitability Apricots, Avocados and Apples

- 6 Infrastructure Development Building a Demand Flywheel

- 7 Machinery and Capital Investment Strategy

- 8 Export Opportunities and Integration of Global Markets

- 9 Risks and Considerations

- 10 Conclusion: A Strategic Location Advantage for Future Ready Manufacturing

- 11 FAQs

Introduction: Port-Based Steel Manufacturing in India

Port-Based Steel Manufacturing in India is transforming the manufacturing sector through improved infrastructure, stronger global trade connections, and advanced logistics systems. The establishment of port-based manufacturing clusters has created integrated industrial ecosystems around major seaports, enabling businesses to enhance production efficiency, streamline transportation operations, and significantly boost export performance.

In industries like steel and heavy fabrication, geography is increasingly becoming a strategic advantage, as opposed to just a logistical consideration. Port-based locations provide businesses with efficient access to both essential raw materials and international markets and institutional buyers which improves their ability to operate efficiently.

For entrepreneurs, investors, and MSMEs looking for long term sustainability, steel manufacturing nearby ports is an attractive opportunity. The implementation of port-centric manufacturing models enables businesses to enhance their operational efficiency through two main methods which include reducing supply chain complexity and fulfilling their regular production needs.

Read More: The Complete Technology Book on Hot Rolling of Steel (2nd Edition)

The Concept of Ports Based Manufacturing Clusters

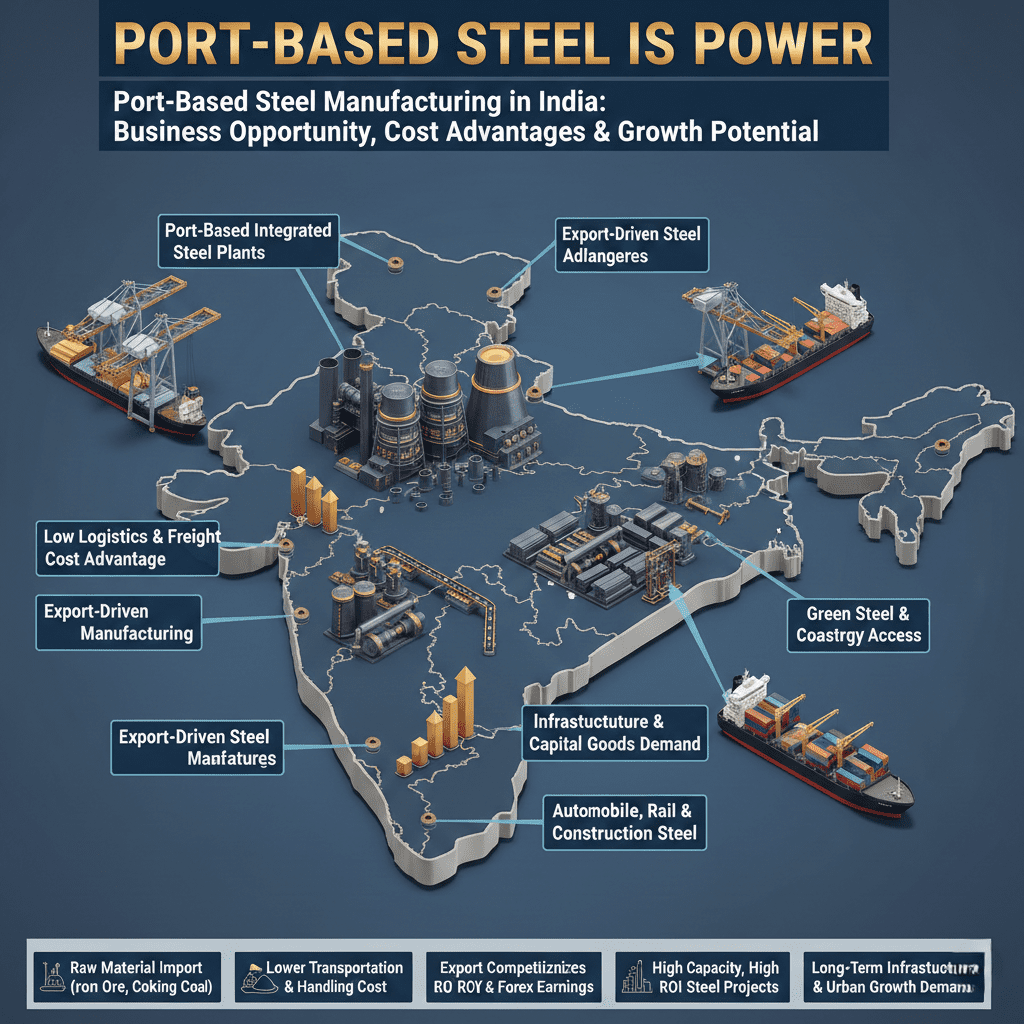

Port-based manufacturing clusters are integrated industrial zones where production facilities are working in the close proximity to maritime infrastructure. These clusters create a complete system which combines all essential elements for manufacturing and logistics operations because they include facilities for production and storage and customs processing and distribution to international markets.(Port-Based Steel Manufacturing in India)

The system creates an efficient value chain which enables direct port access to raw materials and requires minimal handling time to deliver finished products worldwide. Manufacturers benefit from reduced logistics expenses and faster delivery times and improved supply chain reliability.

India’s increasing focus on the economic zones along its coast, port modernization and dedicated freight corridors has spurred the growth of such clusters. Ports are also evolving from transit points into more full-fledged industrial locations which facilitate long-term growth of manufacturing.

Why Steel Manufacturing is the Perfect fit for Port Locations

Steel production and fabrication are inherently logistics heavy activities. The industry depends on large raw materials such as iron ore, scrap metal and coal, while final products – everything from its structural components to its heavy equipment – also need efficient transportation.

Port-based manufacturing solves these challenges by compressing the supply chain:

- raw materials may be acquired from anywhere in the world and transported directly to production facilities.”

- Finished steel products can be exported without the costly inland trucking requirement.

- Inventory storage requirements are reduced because of accelerated shipping cycles.

- Goods handling and material transfer costs are reduced to a great extent.

For manufacturers, these advantages mean better margins and more constant operating expenses. In competitive markets where freight costs are often a major element in profitability, close proximity to ports can be a winning advantage.(Port-Based Steel Manufacturing in India)

Read More: Steel Rolling Technology Handbook (2nd Revised Edition)

Demand Stability through Institutional Buyers

A high strength of the port-based manufacturing is found in its access to institutional and industrial buyers. Ports are complex environments of operation that need constant upkeep, infrastructure upgrade and equipment replacement.

The primary factors which drive demand for this service include:

- Shipping lines & container operators

- Mariner Engineering and EPC Contractors

- Logistics and transportation companies

- Export-oriented manufacturers

- Infrastructure and maintenance agencies

The institutional procurement process uses contract-based operations which operate differently from consumer markets that experience changes based on trends and economic fluctuations. The manufacturing process can create stable production schedules because the system produces consistent demand patterns which help manufacturers achieve constant machine operation throughout their production period.

The current business environment assists MSMEs and mid-sized fabrication businesses to decrease their sales risk while they enhance their ability to predict their financial results.(Port-Based Steel Manufacturing in India)

Steel Product Segments Most Suitable for Port Clusters

Not all steel products have equal benefits from the proximity to the coast. The most successful categories have the following characteristics in common: they have high weight, they have an export orientation, and there is a continuous institutional demand.(Port-Based Steel Manufacturing in India)

Read More: Handbook on Steel Bars, Wires, Tubes, Pipes, S.S. Sheets Production with Ferrous Metal Casting & Processing

Container and Container Component Production

Shipping containers, corrugated panels and structural frames are directly related to port operations. Manufacturing these components in the vicinity of deployment areas curtails the turnaround time and allows for quicker servicing.(Port-Based Steel Manufacturing in India)

Marine and Port Infrastructure Fabrication

Ports require constant maintenance of safety and structural equipment such as bollards, fenders, access platforms, railings, crash barriers, etc. Replacement cycles create constant recurring demand.

Structural Steel for Export Projects

Prefabricated steel structures, which are used in international infrastructure projects, have the advantage of immediate access to the ports. Reduced shipping delay and logistics cost gives coastal fabrication units a strong competitive edge.(Port-Based Steel Manufacturing in India)

Manufacturing of Logistics Equipment

Trailers, skeletal carriers and cargo handling structures suffer intensive use within port ecosystems. Local manufacturing enables fast maintenance support and customer relationship building in the long run.(Port-Based Steel Manufacturing in India)

Read More: Top 20 Steel Manufacturing Business Ideas

Economic Benefits and Profitability Apricots, Avocados and Apples

Port-based steel manufacturing has some structural advantages that lead to long-term financial soundness:

Predictable Logistics Costs: With shorter transportation distances, there is less exposure to volatility and fuel price risk in freight.

Improved Payment Discipline: Institutional clients tend to adhere to structured procurement cycles and contracts, resulting in more predictable payment schedules.

Export Pricing Opportunities: Manufacturers who access international markets can use international pricing standards as their benchmark instead of competing only within their local markets through price wars.

Consistent Production Utilization: A constant demand from industrial activities in setback offers better asset performance at low idle time.

Instead of being at the mercy of volatile market spikers, manufacturers within port clusters tend to enjoy steady margin of EBITDA supported by operation efficiency.

Infrastructure Development Building a Demand Flywheel

The extensive Indian investments in logistics and coastal infrastructure development create more attractive opportunities for port-based manufacturing operations. Key developments include:

- Expansion of Coastal Shipping Networks

- Dedicated freight corridors between industrial regions

- Inland Waterway Connectivity projects

- Modernized systems of cargo handling and containerization

The increase in cargo movement leads to a corresponding rise in equipment wear and the need for maintenance infrastructure. The port operations generate continuous demand which drives the need for manufactured steel components and logistical machinery.

Manufacturers who operate within these ecosystems gain advantages from ongoing industrial production activities instead of relying on single project requirements.(Port-Based Steel Manufacturing in India)

Read More: Top MSME Steel Manufacturing Ideas in India: Almirahs, Slotted Angles & Steel Shots

Machinery and Capital Investment Strategy

Contrary to popular beliefs, port-based steel manufacturing does not have to have extensively specialized or ultra-advanced technology. Success has to do more with the operational efficiency, workflow design, and asset utilization.

Typical equipment includes:

- CNC cutting machines Shearing machines

- Welding stations and fabrication fixtures

- Surface preparation and coating systems

- Cranes Material handling cranes and forklifts

- Management and dispatch infrastructure of yards

Instead of undue levels of automation, manufacturers should be concerned with optimizing production layouts, keeping material movement to a minimum, and ensuring efficient throughput.(Port-Based Steel Manufacturing in India)

Export Opportunities and Integration of Global Markets

The closeness to ports makes it easy to expand exports. Customs infrastructure, bonded warehouses, and digital clearance systems make international transactions easier and eliminate administrative delays.

Export buyers are often interested in suppliers who can coordinate production schedules with vessel departures, manage documentation efficiently and deliver products quickly to shipping terminals. Even smaller fabrication units have access to global markets if they are located in well-connected port ecosystems.

Diversifying revenue through exports also helps manufacturers mitigate fluctuations in domestic demand and helps manufacturers become more financially resilient in the long run.(Port-Based Steel Manufacturing in India)

Risks and Considerations

While manufacturing from port provides great benefits, entrepreneurs should also consider potential obstacles:

- Higher land acquisition/ compliance costs

- Environmental regulations & operational standards

- Dependence on a limited number of institutional buyers

- Need for high levels of logistics co-ordination

However, these risks are usually transparent and manageable through professional feasibility studies, diversified customer portfolios and structured operational planning.

Conclusion: A Strategic Location Advantage for Future Ready Manufacturing

Port-based steel manufacturing is also a forward-looking industry strategy in line with India’s growing global trade footprint. By combining production with logistics infrastructure and institutional demands cycles, manufacturers can reduce uncertainty, optimize supply chains and increase long-term profitability.

As ports develop into a whole industrial ecology, companies who situate themselves within these clusters enjoy predictable demand, export opportunities, and structural cost advantages. For the entrepreneurs and investors looking to expand the steel and fabrication sector in a sustainable way, port-centric manufacturing is bound to play a defining role in the next phase of industrial expansion in India.(Port-Based Steel Manufacturing in India)

FAQs

1.Are port-based manufacturing units appropriate for MSMEs?

Especially yes, the fabrication-oriented steel businesses that cater to institutional buyers.

2.Does the proximity to port ensure demand?

It helps to improve the visibility of demand tremendously, but there is still a need for proper market mapping and contracts.

3.Is export orientation a condition of success?

Not mandatory, but exporting helps to improve the margin stability and diversification.

4.Are compliance requirements stricter near ports?

Yes, environmental and operational regulations are often more but boost industry standards.

5.Which steel products work best in port clusters?

Containers, marine fabrication equipment, structural steel assemblies and logistics equipment.

6.Are inland manufacturers able to compete with port-based units?

They are able to but often have higher logistics expenses and slower delivery cycles.