Introduction: Steel manufacturing startup India

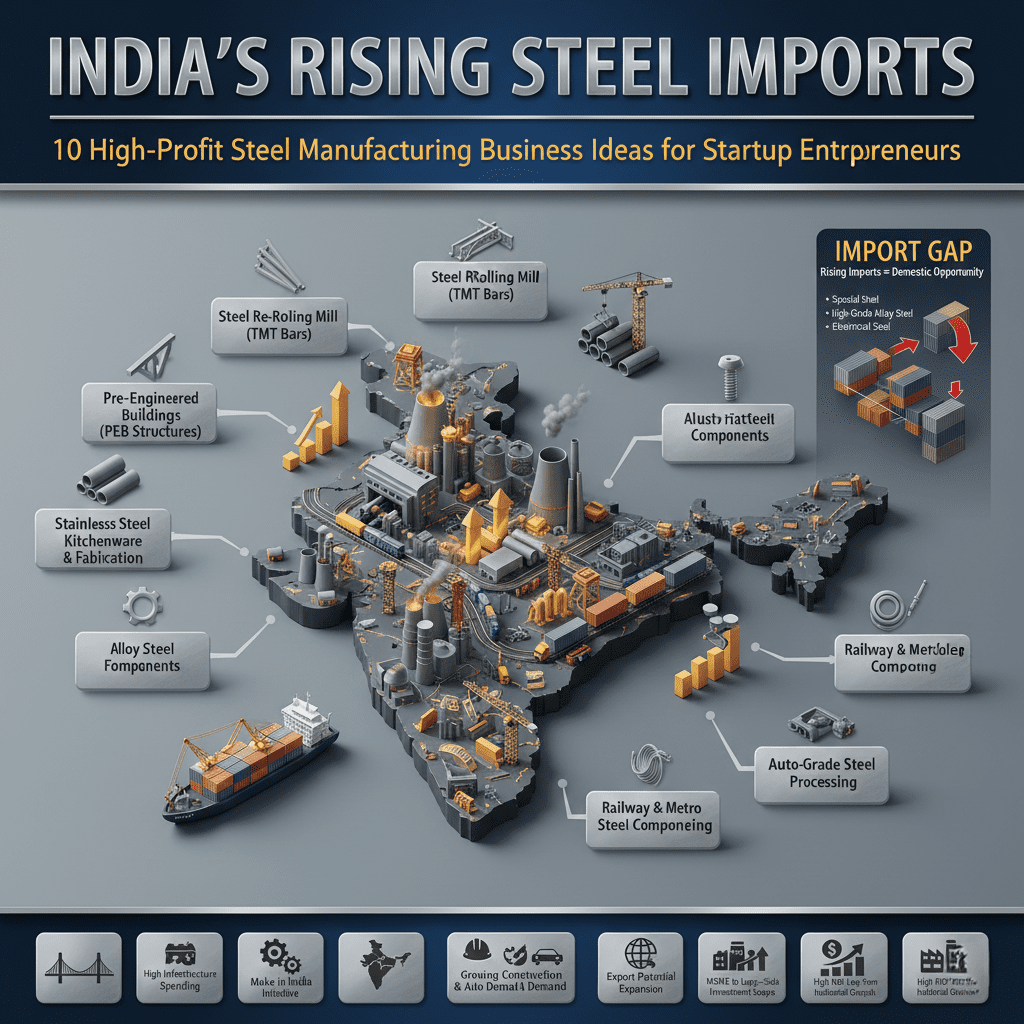

The steel industry in India is currently expanding because three factors are driving the growth of infrastructure and manufacturing capacity and domestic demand for steel. According to information by the Ministry of Steel, between April and December 2024, India has imported more than 7.4 million tonnes of finished steel, indicating a robust demand and the current production gaps.

While the shortage of supplies is evident from imports, there are also tremendous opportunities for entrepreneurs to build profitable manufacturing enterprises as well. Startups are able to enter high-demand segments once again-primarily specialty steel, fabrication, recycling and value-added components, which can capture markets currently dependent on imports.

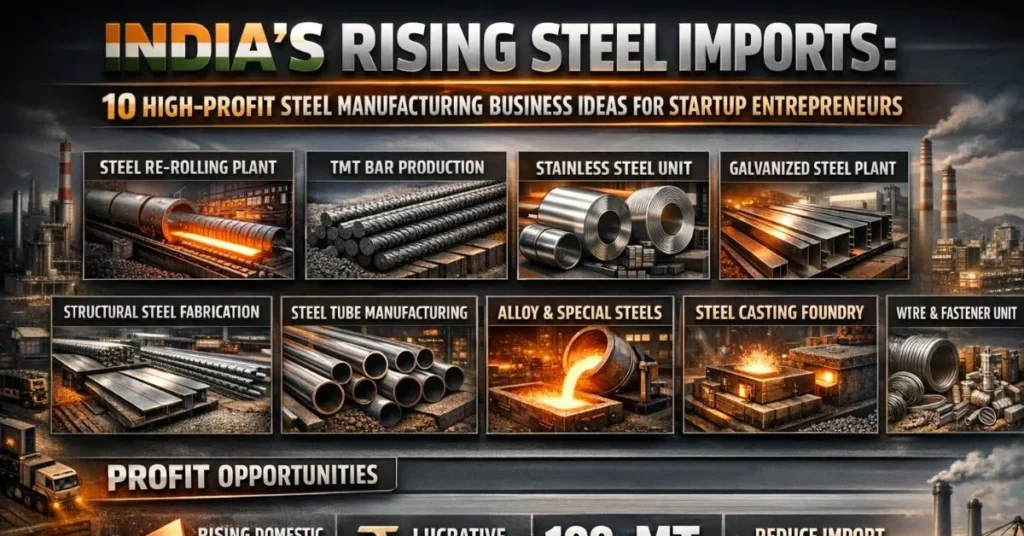

This SEO optimised guide looks at 10 high potential steel manufacturing business ideas that combine with current industry demand, policy incentives and future infrastructure projects.(Steel manufacturing startup India)

Contents

- 1 1. Specialty Steel Production

- 2 2. Cold Rolled Steel Products, Coated Steel Products

- 3 3. Steel Scrap Processing and Recycling (Green Steel Opportunity)

- 4 4. Pellet Production from Low-Grade Iron Ore

- 5 5. Fabricated Steel Structures and Pre Engineered buildings (PEB)

- 6 6. Steel Wire and Fastener Production

- 7 7. Consumer and Industrial Products of Stainless Steel

- 8 8. Foundry Products Made From Pig Iron

- 9 9. Long Products Investment: MSME Driven Induction Furnace Units

- 10 10. Industrial Machinery and Equipment used in Steel Plants

- 11 Inspiration from the Steel Industry Leaders of India

- 12 How Consulting & Feasibility Planning Can Help

- 13 Conclusion: Right Time to Enter India Steel Manufacturing Sector

- 14 Frequently Asked Questions (FAQ)

Read More: The Complete Technology Book on Hot Rolling of Steel (2nd Edition)

1. Specialty Steel Production

Specialty steel is one of the largest import dependent segments in India. High-performance grades such as electrical steel, automotive steel and corrosion-resistant alloys are still sourced from overseas suppliers.

Why it’s a strong opportunity:

- Government incentives in Production Linked Incentive (PLI) schemes

- High demand from EVs, renewables and advanced manufacturing

- Production of transformers and motors increasing

Startup Ideas:

- Electrical steel for power transformers and motors

- High strength automotive steel components

- Manufacturing units of tool steel and alloy steel

Entrepreneurs who have expertise in quality standards and advanced metallurgy can compete directly with imported items.(Steel manufacturing startup India)

2. Cold Rolled Steel Products, Coated Steel Products

Cold-rolled sheet and coated steel are used extensively in appliances, automobiles, construction and industrial machinery. Demand is still increasing with the rising infrastructure sector in India.

Business Opportunities:

- Colour-coated roofing sheets

- Galvanized steel panels

- Industrial production of cold rolled sheet

Small and medium manufactures can begin with downstream processing units instead of the full steelmaking operations, which reduces the risk of investment.(Steel manufacturing startup India)

3. Steel Scrap Processing and Recycling (Green Steel Opportunity)

Sustainability is changing the steel industry. Recycling helps lower emissions as well as aligns India’s green steel roadmap.

High-Demand Areas:

- Scrap shredding and segregation plants

- End-of-life vehicle dismantling centres

- Ferrous scraps supply to induction furnace operators

Recycling businesses have lower capital requirements than primary steelmaking and have the advantage of increasing environmental regulations.(Steel manufacturing startup India)

4. Pellet Production from Low-Grade Iron Ore

India produces large volumes of iron ore but a significant part of this is low grade. This is then pelleted into an efficient raw material for steel plants.

Startup Advantages:

- Strong demand by sponge iron and integrated steel producers

- Possibility to operate in the vicinity of mining clusters

- Reduced transportation costs if it is strategically located

Pellet plant can become essential suppliers as steel plant focus on efficiency and cost reduction.

5. Fabricated Steel Structures and Pre Engineered buildings (PEB)

India’s infrastructure expansion including high ways, logistics parks, metro rail, and renewable energy projects has led to a demand for fabricated steel structures.

Segments of Products That Generate Profit:

- Pre-engineered building components

- Transmission towers – Telecommunication structures

- Solar mounting systems

- Industrial Warehouses and Modular Buildings

Fabrication companies stand to gain rapid growth by partnering with EPC contractors and infrastructure development companies.(Steel manufacturing startup India)

6. Steel Wire and Fastener Production

High-precision steel wire products can be imported on a large scale in light of strict quality requirements.

Manufacturing Opportunities:

- Wire drawing And Heat Treating Units

- Galvanized agricultural fencing wire

- Industrial springs and fasteners

- Power transmission cables and reinforcement mesh

Precision engineering and quality control can also aid in new manufacturers moving into export markets.

Read More: Steel and Iron Handbook

7. Consumer and Industrial Products of Stainless Steel

Increasing urbanization and lifestyle changes are driving the increase in demand for stainless steel products in the construction and consumer market.

Business Opportunities:

- Stainless steel pipe and tubes

- Kitchenware and utensils

- Architectural fittings and railings

- Modular kitchen components

High grade stainless steel manufacturing helps in reducing the dependence on imports while catering to the domestic demand.(Steel manufacturing startup India)

8. Foundry Products Made From Pig Iron

Foundry products such as cast iron products are needed in automotive, machinery and pump manufacturing.

Potential Business Areas:

- Cast iron automotive parts

- Industrial valves and pump housings

- Agricultural Machinery Components

Foundries may serve both the domestic industries as well as to export markets in Asia and the Middle East markets.(Steel manufacturing startup India)

9. Long Products Investment: MSME Driven Induction Furnace Units

Induction furnace technology enables smaller manufactures to produce structural steel products with relatively low capital investment.

High-Demand Products:

- TMT bars for construction

- Angles, beams, and channels

- Rural and semi-urban construction Steel

Faster growing towns have local markets to be serviced by a regional mini-mill.

10. Industrial Machinery and Equipment used in Steel Plants

As the steel capacity increases, so does the demand for localised machinery and automation systems.

Business Ideas:

- Material handling systems, conveyors.

- Pollution control equipment

- Plant automation and robotics

- Engineering and EPC support services

Supplying equipment to steel manufacturers presents recurring revenue opportunities.

Inspiration from the Steel Industry Leaders of India

Entrepreneurs who are looking to get into the steel industry can learn from iconic steel industry leaders:

- Ratan Tata turned Tata Steel into a globally focused technology company.

- Sajjan Jindal grew JSW Steel by innovation and strategic expansion

- Lakshmi Mittal built ArcelorMittal to one of the largest producers of steel in the world.

Their journeys show that innovation, efficiency and global thinking are the keys to being successful in the steel business.

How Consulting & Feasibility Planning Can Help

Before setting up a manufacturing business, entrepreneurs must generate elaborate feasibility reports related to financial planning, machinery selection, and market analysis. Consulting firms like Niir Project Consultancy Services help in reducing the risks and better investment decisions by offering techno-economic feasibility studies.(Steel manufacturing startup India)

Conclusion: Right Time to Enter India Steel Manufacturing Sector

India’s increasing steel imports show that the country has major production deficits while its domestic demand continues to expand. Entrepreneurs who invest in specialty steel recycling fabrication and industrial equipment will develop businesses that can grow and succeed in the future.

With the strong support of government, expansion of infrastructure and sustainability programs, the next decade offers up huge possibilities for innovative manufacturing startups who are willing to act early and strategically.(Steel manufacturing startup India)

Frequently Asked Questions (FAQ)

1.why are steel imports increasing in India?

Steel imports are rising due to rapid infrastructure growth, increased manufacturing demand, and shortages in specialty and high-quality steel segments.

2.Which steel manufacturing business is best for beginners?

Downstream industries such as fabrication, wire products, recycling, and stainless steel consumer goods require lower investment compared to integrated steel plants.

3.Is specialty steel manufacturing profitable?

Yes, specialty steel offers high margins due to strong demand from automotive, electronics, renewable energy, and engineering sectors.

4.What is the minimum investment required to start a steel business?

Investment varies widely—from small fabrication units starting with moderate capital to large pellet or specialty steel plants requiring substantial funding.

5.How can startups compete with imported steel products?

By focusing on quality standards, localized supply chains, advanced manufacturing technology, and niche product segments.

6.Are government incentives available for steel manufacturing startups?

Yes, schemes such as PLI for specialty steel, MSME incentives, and sustainability initiatives support new manufacturing businesses.

7.What is the future of green steel in India?

Green steel and recycling are expected to grow rapidly as industries focus on carbon reduction and environmentally sustainable manufacturing.