Electrical Components Manufacturing Opportunities in India 2026. India is not “upgrading”, it is rebuilding its power sector at scale. Transmission expansion, renewable infrastructure, smart grids, and metro rail electrification are all converging to create one reality: a sustained demand for electrical component manufacturing.

This is not a speculative market. It is infrastructure-backed demand driven by grid expansion, replacement of aging assets, and new energy systems. This sector is a great opportunity for MSMEs and the first generation of manufacturers. It offers predictable volume, repeat procurement, and export viability if you enter with the right product logic.

This article explains the real manufacturing opportunities and which product categories are most profitable. It also explains how investors can evaluate their entry, without hype or fluff.

Contents

- 1 Why Manufacturing Electrical Components is a Good Business Decision Now

- 2 Electrical Components Manufacturing Segments with High Demand

- 2.1 1. Distribution Transformer Manufacturing (16kVA-2500kVA)

- 2.2 2. Switchgear Manufacturing (LT & HT).

- 2.3 3. Electric Motor Manufacturing and Industrial Drives

- 2.4 4. Power Cable Manufacturing

- 2.5 5. Electrical Control Panels & Automation Systems

- 2.6 6. Solar Electrical Components Manufacturing

- 2.7 7. Smart Grid and Metering components

- 2.8 8. Power Distribution Hardware & Accessories

- 3 Import Substitution Logic and Export Logic

- 4 India’s Power Sector Industrial Leaders: Lessons to be Learned

- 5 Conclusion: Electrical Manufacturing is a Wealth Builder for the Long-Term

- 6 FAQs

Why Manufacturing Electrical Components is a Good Business Decision Now

1. The Growth of Electricity Demand

Electricity consumption is on the rise due to urbanization, the adoption of EVs, industrial expansion, and digital infrastructure. Electrical equipment demand increases before electricity consumption peaks, making manufacturers early beneficiaries.

2. Grid modernization is equipment-intensive

Continuous procurement is required for:

- Transformers

- Switchgear

- Protection devices

- Control panels

- Metering systems

It is not a one-time capital expenditure, but a demand for replacements.

3. Renewable Energy Increases Component Consumption

Solar and wind power plants consume more electrical equipment per MW compared to conventional plants, resulting in a higher demand for transformers and cables.

4. Import dependency creates entry gaps

India continues to import advanced motors, switchgear components and power electronics. This is a clear indication of production gaps rather than market saturation.

Related Article:- Electronic Project

Electrical Components Manufacturing Segments with High Demand

Segmentation of the Electrical Components Market: INFOGRAPHIC

1. Distribution Transformer Manufacturing (16kVA-2500kVA)

India’s electrification campaign is centered around distribution transformers. They are required by every housing cluster, industrial park, renewable plant and substation.

Product Scope

- Transformers with oil-filled tanks

- Dry-type transformers

- Transformers for solar inverters

- Compact substations

Business Logic

- High unit value

- Continuous replacement demand

- MSMEs have a significant market share

[IMAGE] Distribution Transformer Applications

2. Switchgear Manufacturing (LT & HT).

Switchgear demand directly correlates with infrastructure growth. Isolation, protection, and control are essential for every power system, whether industrial or commercial.

Manufacturing Scope

- MCBs are also known as MCCBs and ACBs

- Contactors and Isolators

- Ring Main Units

- Fusegear assemblies and protection assemblies

Why This Segment is Stable

- Infrastructure-linked demand cycles

- Customers include utilities, EPCs and industries

- Scalability of modular manufacturing

View our:- Books

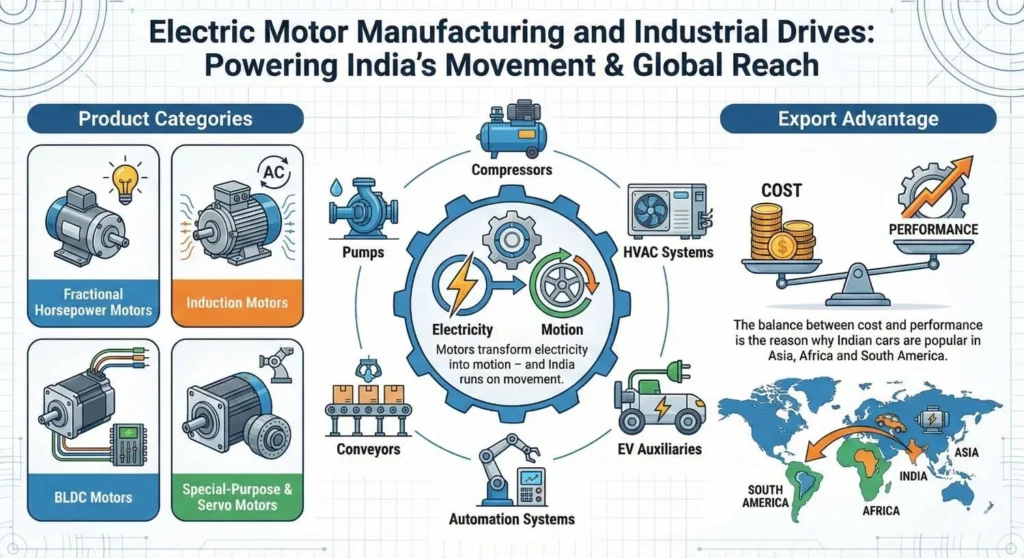

3. Electric Motor Manufacturing and Industrial Drives

Motors transform electricity into motion – and India runs on movement. They are essential for pumps, compressors, and HVAC systems, as well as conveyors, automation systems, and EV auxiliaries.

Product Categories

- Motors with fractional horsepower

- Induction motors

- BLDC motors

- Special-purpose motors and servo motors

Export Advantage

The balance between cost and performance is the reason why Indian cars are popular in Asia, Africa and South America.

4. Power Cable Manufacturing

Cables are essential to the operation of any electrical system. Cables are products that are frequently ordered and in high demand.

Product Lines

- LT & HT Cables

- Cables FRLS/FRLSH

- Control and instrumentation cable

- Solar DC cables

- Bunched aerial cables

Commercial Reality

- Lower margin per unit

- High volume

- Strong contractor-driven repeat sales

5. Electrical Control Panels & Automation Systems

Control panels are customizable products that are ideal for MSMEs who compete on engineering, service and scale alone.

Manufacturing Options

- LT, MCC, PCC panels

- DG synchronization panel

- PLC & SCADA panels

- Solar junction boxes

Why MSMEs Win Here

Customization is a barrier to entry for mass producers.

6. Solar Electrical Components Manufacturing

Demand for electrical components in balance of system systems increases automatically with the growth of renewable capacity.

High Demand Products

- Solar DC distribution boards

- Combiner boxes

- Surge protection devices

- Earthing Kits

- Solar lighting controllers

This segment is a beneficiary of ‘s policy continuity and export-relevant.

7. Smart Grid and Metering components

India’s move to smarter electricity networks is technology-driven and component-heavy.

Startup-Friendly Products

- Smart energy meters

- Communication Modules

- Load monitoring devices

- IoT energy controllers

This is a technology-manufacturing hybrid–not suitable for everyone, but powerful for capable teams.

View:- Project Report

8. Power Distribution Hardware & Accessories

Products with low complexity and low demand.

Products

- Insulators (polymer/porcelain).

- Earthing Materials

- Line clamps, connectors, and other accessories

- Conductors and Fasteners

Why This Work

- Utility demand is predictable

- Reduced technology risk

- Easier certification

Import Substitution Logic and Export Logic

[INFOGRAPHIC: Import and Export Opportunity Map]

Imported

- Specialized motors

- Advanced switchgear components

- High-frequency Transformers

- Control electronic devices

Export-Ready Products

- Transformers

- Cables

- Electrical Hardware

- Motor components

Export acceptance or import gaps can help manufacturers win more quickly.

India’s Power Sector Industrial Leaders: Lessons to be Learned

India’s power equipment ecosystem was created by long-term planners who understand infrastructure cycles, not short-term profits.

Their success confirms a truth: Electrical Manufacturing rewards patience, scale discipline and technical consistency.

Watch:- Youtube Channel

Conclusion: Electrical Manufacturing is a Wealth Builder for the Long-Term

India is building one of the largest and most complicated power systems in the world. This will ensure a sustained demand for:

- Transformers

- Motors

- Switchgear

- Cables

- Panels

- Smart-grid devices

This sector has a lot to offer manufacturers:

- Demand Long-term visibility

- Infrastructure-backed growth

- Import substitution leverage

- Export scalability

Electrical component manufacturing is not trendy; it is structural. It works because it is effective.

Are you serious about starting a business in the manufacturing of electrical components?

The wrong assumption regarding capacity, product mix, or compliance can lead to a loss.

Before investing capital, commission a DPR or a study of techno-economic feasibility.

How NPCS Can Help

NPCS (Niir Project Consultancy Services) provides end-to-end support for entrepreneurs, including:

- Detailed Project Reports (DPR).

- Financial modeling & ROI analysis.

- Plant layout & machinery selection.

- Vendor & buyer connect.

- Licensing & compliance guidance.

With expert support, your chances of success in this high-growth sector increase significantly.

Niir Project Consultancy Services

106-E, Kamla Nagar, Opp. Mall ST,

New Delhi-110007, India.

Email: info@entrepreneurindia.co

Mobile: +91-9097075054

Website:https://www.entrepreneurindia.co

FAQs

1. Which electrical products are easiest for new manufacturers?

Cables, control panels, and LT switchgear components offer lower entry barriers.

2. Is export viable for MSMEs?

Yes. Transformers, cables, motors, and hardware have strong overseas demand.

3. Typical investment range?

?40–80 lakh for basic units; transformer plants require higher capital.

4. Does policy support exist?

Yes. Open FDI, manufacturing incentives, and infrastructure spending support the sector.

5. Can NPCS prepare a DPR for my project?

Yes. NPCS delivers complete feasibility and financial reports for electrical manufacturing units.