Contents

- 1 Packaging Infrastructure: A Better Investment than Consumer Products

- 2 From product thinking to packaging infrastructure thinking

- 3 Why startups and MSMEs have an advantage in paper bottle production

- 4 Paper Bottles: The Engineering Logic Behind Them

- 5 Manufacturing as a service: A smarter revenue model

- 6 First-time manufacturers are favored by capacity economics

- 7 Multinational beverage brands are not the only drivers of demand

- 8 Export of Empty Bottles and Not Filled Beverages

- 9 Learn from Industry Leaders: Control Dependency

- 10 Startup Models that Scale

- 11 Why Feasibility planning is non-negotiable

- 12 Last Thought: Build what the industry cannot operate without

- 13 FAQs

Packaging Infrastructure: A Better Investment than Consumer Products

Paper Bottle Manufacturing Business – An Infrastructure-Led Opportunity in Beverage The majority of startups fail because they are too close to the volatility of consumers. Demand fluctuates, brand costs increase, and pricing power is rapidly eroded.

Packaging is a completely different industry.

The paper bottle business represents the next step in this logic. The paper bottle is not seen as an eco-friendly product, but rather as the core infrastructure of the future beverage industry. Packaging is upstream and locked in production lines, logistic systems, and long-term supply contracts.

Paper bottle production is a rare opportunity for first-generation entrepreneurs, MSME investors, and MSME buyers.

- Stable industrial demand

- Contract-backed revenue

- Deep Supply Chain Integration

Paper bottles are no longer viewed as an innovation in product design, but rather as a necessity. Packaging infrastructure for beverages: New Startups with Infrastructure as the Main Driver.

From product thinking to packaging infrastructure thinking

Most manufacturing entrepreneurs think in terms of units sold. Infrastructure-led businesses consider:

- Capacity utilization

- Long-term Offtake Agreements

- Customer dependency

Paper bottles clearly belong to the second category.

Switching suppliers is expensive and disruptive for a beverage company that has redesigned its filling lines, branding, compliance systems, and logistics around paper bottles. It creates structural lock-in, which is rare for startups.

Paper bottle plants are characterized by:

- Toll roads are used by many brands

- The beverage industry has a utility that is embedded in its operations.

- A long-term provider of services, not just a vendor for transactions

The mindset of the company determines if it will grow or not.

Related Article:- Paper Industry

Why startups and MSMEs have an advantage in paper bottle production

The structure of large packaging companies is slow. Glass and plastic packaging ecosystems are capital-intensive, legacy-driven, and resistant to change.

These constraints do not apply to startups.

New entrants in the paper bottle business can benefit from:

- Greenfield plant optimized for paper-based formats

- Contract execution for emerging beverage brands is faster

- Flexible customisation for niche products and private labels

- Reduce internal resistance to material innovations

This allows MSME entrepreneurs to compete with established players by focusing on their execution.

Paper Bottles: The Engineering Logic Behind Them

The paper bottles are effective because they divide functions in a clever way.

Outer Paperboard Shell

- Strengthening the structure

- Form and rigidity

- Branding and the consumer experience

Inner Liner

- Food safety regulations

- Liquid containment

- Shelf life protection

The modular design is important commercially.

Paper bottle production, unlike glass or polymer bottle plants, is:

- Assembly is not chemistry-driven

- Low-temperature, low-energy

- Dependent on mechanical integration instead of complex reactions

This reduces the risk of failure for new manufacturing enterprises.

Manufacturing as a service: A smarter revenue model

Manufacturing As A Service is one of the packaging models that are underused.

Paper bottle manufacturers should not compete on the basis of price per unit but instead, they can be positioned as:

- Bottlers can find packaging partners on-site.

- Paper Bottle Services in Regional Areas

- Contract Manufacturers with Reserved Capacity

Customers do not purchase bottles in this model. Instead, they buy access to capacity.

Transactional sales revenue shifts to:

- Volume commitments monthly

- Reservation fees for annual capacity

- Supply agreements for multiple years

This model improves the ability to service debt and stabilises cash flows, which is critical for MSME scale manufacturing.

A detailed feasibility and capacity study is a must if you are evaluating paper bottle manufacturing businesses. A professional techno-economic study prevents overcapitalisation and mismatches in demand.

View our:- Books

First-time manufacturers are favored by capacity economics

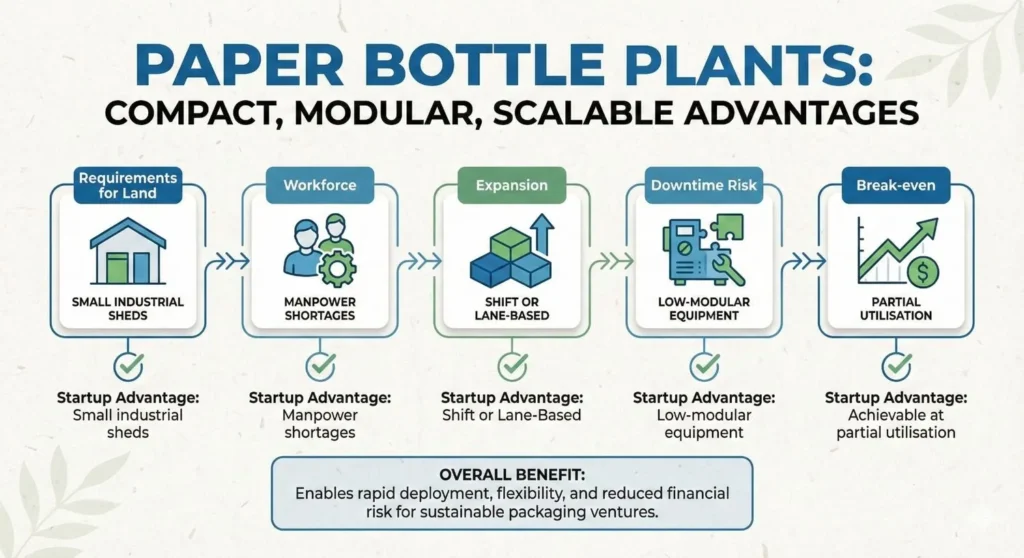

Paper bottle plants can be compact, modular, and scalable.

| Parameter | Startup Advantage |

|---|---|

| Requirements for Land | Small industrial sheds |

| Workforce | Manpower shortages |

| Expansion | Shift or Lane-Based |

| Downtime Risk | Low-modular equipment |

| Break-even | Achievable at partial utilisation |

It allows the founder to validate their operations and expand without affecting cash flow.

Multinational beverage brands are not the only drivers of demand

It is a common misconception that only the global beverage giants are important.

The early demand for paper bottles is driven by:

- Craft spirit producers

- Boutique wineries

- Private-label retail brands

- Chains of QSR and hospitality

- Export-oriented beverage startup

They see sustainable packaging as a differentiation of the brand and not as regulatory compliance. These players are more flexible and quicker in their decision-making. They also welcome long-term partnerships.

This demand profile is perfectly aligned with the manufacturing scale of MSMEs.

View:- Project Report

Export of Empty Bottles and Not Filled Beverages

Exporting empty paper bottles is a logistically efficient way to export beverages.

The following are some of the advantages:

- Glass is less expensive to ship.

- Container weight reduction

- Easier international handling

Paper bottle producers can serve as regional hubs for exporting goods to overseas bottlers.

This is in line with the Ministry of Commerce and Industry’s export-led manufacturing goals, particularly where sustainability increases global competitiveness. New Startups with Infrastructure as the Main Driver.

Learn from Industry Leaders: Control Dependency

India’s most successful industrialists didn’t start with consumer brands.

You built:

- Cement plants

- Packaging Units

- Hubs for logistics

- Component manufacturing facilities

The basic principle is straightforward:

You can control what others depend on.

The same logic applies to the manufacture of paper bottles. Beverage brands can change. Packaging infrastructure does not.

Infrastructure-led manufacturing outperforms consumer startups consistently over the long-term.

Startup Models that Scale

Some of the most viable paper bottle business models are:

Regional Packaging Utility

Serve all beverage producers in a specified radius.

Export-Focused Manufacturing Platform

Unfilled bottles can be supplied to international bottlers.

Integrated Sustainable Packaging Unit

Combining paper bottles with secondary packaging and cartons.

Private Label Contract Manufacturing

Produce exclusive designs for retail chains.

The model’s growth is based on the demand of the customer, and not in advance.

Why Feasibility planning is non-negotiable

The industry rewards those who are disciplined, not the optimistic.

The following are key success factors:

- Demand assessment is accurate

- Modeling of capacity utilisation

- Machine Selection Logic

- Raw Material Cost Stability

- Planning for long-term scaling

Niir Project Consultancy Services’ feasibility studies are based on actual operational economics and not just brochure projections. This improves bankability and prevents capital misallocation. New Startups with Infrastructure as the Main Driver.

Last Thought: Build what the industry cannot operate without

The paper bottles are changing the way beverages are packaged and distributed.

The paper bottles manufacturing business does not appeal to founders who are looking for quick exits or hype cycles.

This is for entrepreneurs who want to create manufacturing assets on which the beverage industry can become structurally dependent.

Watch:- Youtube Channel

How NPCS Can Help

NPCS (Niir Project Consultancy Services) provides end-to-end support for entrepreneurs, including:

- Detailed Project Reports (DPR).

- Financial modeling & ROI analysis.

- Plant layout & machinery selection.

- Vendor & buyer connect.

- Licensing & compliance guidance.

With expert support, your chances of success in this high-growth sector increase significantly.

Niir Project Consultancy Services

106-E, Kamla Nagar, Opp. Mall ST,

New Delhi-110007, India.

Email: info@entrepreneurindia.co

Mobile: +91-9097075054

Website:https://www.entrepreneurindia.co

FAQs

Can this be used by first-time entrepreneurs?

With professional planning and technical onboarding, yes.

Is the business dependent on sustainability subsidies?

Sustainability accelerates adoption, but economics drive it.

Is it better to have fewer clients than more?

No. Anchor clients with a long-term relationship are preferred.

Does the technology pose a risk?

no. Once it is in operation, the machine will remain mechanically stable.

What is the required mindset? Be an infrastructure builder and not a product vendor.