Contents

- 0.1 Ferro Alloys Industry

- 0.2 Global Ferro Alloys Market Overview (2025-2030)

- 0.3 Major Types Of Ferro Alloys

- 0.4 Application of Ferro Alloys

- 0.5 Ferro Alloys Production Process

- 0.6 Machines and Equipment Used

- 0.7 Raw Material Required

- 0.8 How To Start A Ferro Alloys Manufacturing Business

- 0.9 Tips to a More Efficient Production Setup

- 0.10 Why Entrepreneurs Should Invest In Ferro Alloys

- 0.11 Future Outlook (2025-2035)

- 0.12 Conclusion

- 1 Frequently Asked Question

Ferro Alloys Industry

Iron alloys are used in many industries, including metallurgy and engineering. They are composed mainly of ferrous, combined with silicon, manganese, and chromium.

Ferroalloys include:

- Ferro Silicon High Carbon: A ferro-silicon alloy with a higher carbon content. It is used to increase the hardness and strength of steel and cast iron.

- Ferro manganese: An important deoxidizing agent and alloying agent used in steelmaking. Also used to make other alloys such as ferronickel or ferrochrome.

- Silico Manganese: A combination containing silicon, manganese, and iron, which strengthens steel, improves corrosion resistance, and increases its wear resistance.

Global Ferro Alloys Market Overview (2025-2030)

The global market for ferroalloys is continuing to grow, with the support of increasing steel demand, increased infrastructure, and expanded automotive production.

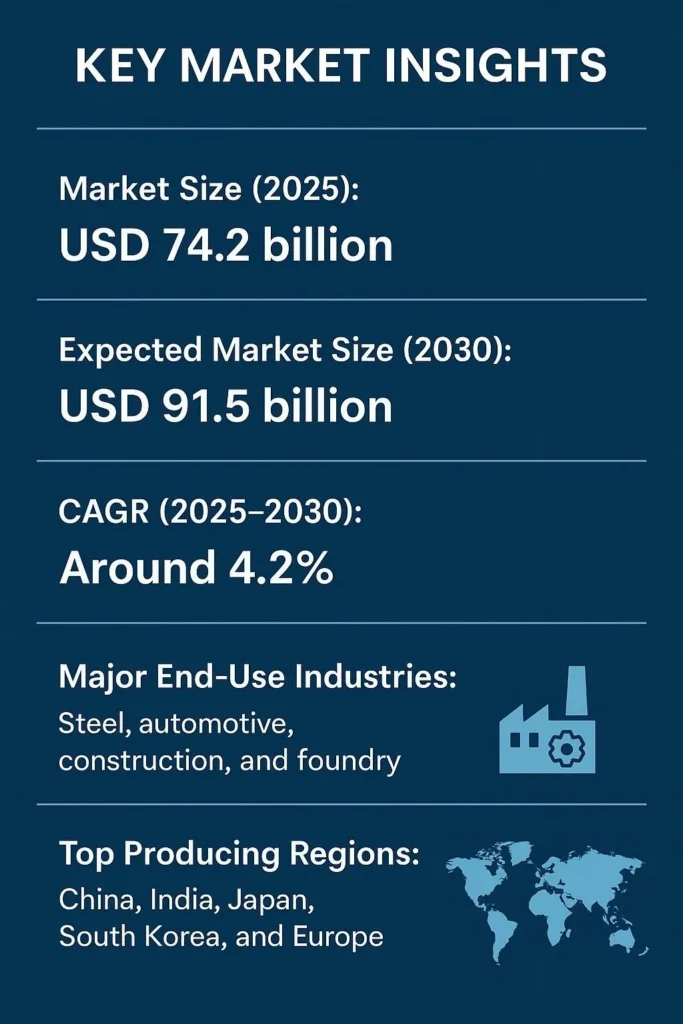

Key Market Insights

- Market Size (2025): USD 74.2 billion

- Expected Market Size (2030): USD 91.5 billion

- CAGR (2025-2030): Around 4.2%

- Major end-use industries: steel, automotive, construction, and foundry

- Top producing regions: China (India), Japan, South Korea, and Europe

Growth Drivers

- Demand for corrosion-resistant and high-quality steel

- Infrastructure development in emerging economies

- Growth of renewable energies and electric vehicles (EV) sectors

- The use of recycled Steel is increasing, but still requires ferroalloy additions

Challenges

- Raw material prices that are volatile (manganese, quartzite and coke).

- High Energy Consumption during Smelting

- Costs of environmental compliance

Related Article on:- Ferro alloys

Major Types Of Ferro Alloys

1. Ferro Silicon High Carbon

- Reduced quartzite, coke, and iron scrap.

- In steelmaking, it acts as an oxidizer and strengthener.

- Cast iron is given a higher hardness and corrosion resistance.

2. Ferro Manganese

- The coke is made by melting manganese ore in an electric furnace.

- Use to remove sulfur and oxygen from steel.

- Alloys with improved mechanical toughness and strength.

3. Silico Manganese

- In a furnace, manganese, quartz, and coke are combined.

- It is used in the steel industry as a deoxidizing agent.

- Useful in steel construction for increasing hardness and tensile strength.

Application of Ferro Alloys

Ferroalloys are essential in the modern industrial world, particularly in:

- Steel production

- Aluminum alloys and magnesium alloys

- Automotive components

- Industrial tools and welding electrodes

- Catalysts for chemical production

Ferro Alloys Production Process

Ferroalloys are manufactured using several metallurgical processes to ensure consistency in composition and quality.

Step-by-Step Process

- Ore Beneficiation Crushing and washing ore, followed by sieving to remove impurities.

- Smelting Heat ore in a submerged arc furnace (SAF) to over 1,000 °C separates metal elements.

- Alloying: Add silicon, manganese, and carbon to specific grades.

- Forming and Casting: Pouring molten metal into molds in order to form lumps or ingots.

- Finishing and Quality Control: Cooling down, treating, testing, and meeting international standards (IS ASTM EN).

Machines and Equipment Used

- Submerged Arc Furnace

- Electric Induction Furnace

- Crushers and Pulverizers

- Conveyors and Feed Systems

- Pollution Control Units and Dust Filtration Units

- Composition Testing with Spectro Analyzers

- Cooling and Casting Units

Raw Material Required

| Raw Material | Purpose | Source |

|---|---|---|

| Manganese Ore | Main component for ferro manganese & silico manganese | India and South Africa |

| Quartzite / Silica | Ferro silicon source | Rajasthan and Andhra Pradesh |

| Coke / Charcoal | Reducing agent | Both domestic and imported |

| Iron Scrap/ Iron Ore | Iron base | Local steel mills |

| Graphite / Carbon | Carbon enrichment | Jharkhand is located in China |

| Flux (Limestone / Dolomite) | Impurity removal | Indian mineral belts |

View Book on:- Ferro alloys

How To Start A Ferro Alloys Manufacturing Business

1. Market Research – Detailed

Export markets and domestic demand trends should be studied.

2. Get the necessary licenses

You’ll need:

- Pollution Control Board NOC

- Environmental Clearance

- Registration of Labor and Factory License

- BIS Certification quality and exports

3. Select the Ideal Location

Choose a location near:

- Raw material sources

- Reliable water and electricity supply

- Transportation routes (road, rail, port)

4. Estimate Investment Requirements

- Plant capacity: From 5 MVA up to 30 MVA for furnace setup

- Investment range: Rs30 to Rs120 crore for small and medium units

- Land requirement: between 5-20 acres depending on scale

5. Build Your Team

Employ technical supervisors , skilled metallurgists and furnace operators.

Tips to a More Efficient Production Setup

- Reduce human error by automating processes using PLCs-based control systems.

- Install energy efficient furnaces, and waste heat recovery systems.

- Keep strict testing of chemical composition and performance.

- Use to collect dust and dispose of waste in an eco-friendly manner.

Why Entrepreneurs Should Invest In Ferro Alloys

1. Consistent global demand

Steelmaking accounts for over 85% ferroalloys.

2. Strong Domestic Advantage in India

- India is one of the three largest ferroalloy producers in the world.

- Access to manganese ore, chrome ore and iron ores is abundant.

- Government policies that support “Make In India” or the PLI Schemes.

3. High Export Potential

Exports to Japan South Korea Europe and the Middle East.

4. Attractive Profit Margin

- A gross margin of 12-20% is possible with efficient operations.

- Steel producers can offer stability by signing long-term contracts of supply.

5. Eco-Friendly Business Model

Ferroalloys comply with global sustainability, green steel movement.

Future Outlook (2025-2035)

| Emerging Trend | Industry Impact |

|---|---|

| Green Ferroalloys | Switch to low-emission renewable energy furnaces |

| Digital Automation | AI and IoT used for energy optimization and process control |

| Recycling Integration | Recovering alloys from steel scrap and slag |

| Government Incentives | Support for sustainable and export-oriented alloy units |

Forecast: The global ferroalloys market is expected to exceed USD 120 billion by 2035. This will be driven by the demand for green steel and infrastructure expansion in Asia and Africa.

Conclusion

Ferroalloys, such as Ferro Silicon High Carbon (FSC), Ferro Manganese and Silico Manganese, are at the heart of modern steel production.

Launching a Ferro Alloys Manufacturing Plant means investing today in a business which will ensure steady demands, strong export potential and sustainable profitability over the next few decades.

Project Report on :- Ferro Alloys Industry

How NPCS Can Help You

NPCS (Niir Project Consultancy Services) provides end-to-end support for entrepreneurs, including:

- Detailed Project Reports (DPR).

- Financial modeling & ROI analysis.

- Plant layout & machinery selection.

- Vendor & buyer connect.

- Licensing & compliance guidance.

With expert support, your chances of success in this high-growth sector increase significantly.

Niir Project Consultancy Services

106-E, Kamla Nagar, Opp. Mall ST,

New Delhi-110007, India.

Email: info@entrepreneurindia.co

Mobile: +91-9097075054

Website:https://www.entrepreneurindia.co

Frequently Asked Question

What are ferro alloys and why are they important in the steel industry?

Ferro alloys are alloys made by combining iron with one or more elements such as manganese, chromium, silicon, or nickel. They play a crucial role in the steel industry because they improve the strength, hardness, corrosion resistance, and overall quality of steel. Without ferro alloys, modern steel production—used in construction, automobiles, infrastructure, and machinery—would not be possible at an industrial scale.

How are ferro alloys manufactured in the ferro alloys industry?

The manufacturing process of ferro alloys mainly involves the reduction of metal oxides using carbon in electric arc or submerged arc furnaces. Raw materials such as iron ore, coke, quartz, and specific metal ores are processed at very high temperatures. This energy-intensive process requires reliable power supply and advanced furnace technology, which is why ferro alloy plants are usually set up near power sources and raw material hubs.

What are the key market trends and growth drivers in the ferro alloys industry?

The ferro alloys market is driven by rising global steel production, infrastructure development, and demand from the automotive and construction sectors. Rapid industrialization in emerging economies, especially in Asia, has significantly boosted demand. Additionally, technological advancements, energy-efficient furnaces, and increased focus on sustainable manufacturing practices are shaping the future growth of the ferro alloys industry.

What business opportunities exist in the ferro alloys sector for new investors?

The ferro alloys sector offers strong business opportunities due to consistent demand from steel manufacturers. Investors can explore opportunities in setting up manufacturing units, raw material supply, export-oriented production, and value-added ferro alloy products. With government support, growing domestic consumption, and export potential, the ferro alloys industry presents long-term profitability for entrepreneurs and industrial investors.